The thorny problem of what to do with Britain’s growing stockpile of civil separated plutonium waste continues to test the minds of nuclear engineers.

Over many decades, around 140 tonnes have been produced from a range of spent fuel types in a variety of facilities. The composition is therefore variable, with most of the material well characterised and of good quality, but with smaller portions contaminated or in the form of residues or mixed-oxide scraps.

One interesting solution, being put forward by Canadian firm Candu, would be to turn the stockpile into MOX pellets at a dedicated fabrication facility at Sellafield in Cumbria, and use that material in four thermal reactors, producing 3GWe of power for sale in the electricity market. Candu’s proposal has emerged as a front-runner among options under consideration by the Nuclear Decommissioning Authority (NDA), as it could deal with the entire stockpile, regardless of the grade or contamination.

The Institution of Mechanical Engineers has been involved with the assessment of the Candu solution, and from an engineering perspective it has proved an attractive option.

“One opportunity that Candu raises is the ability to deal with the range of materials that make up the stockpile,” says Tim Fox, the IMechE’s outgoing head of energy and environment, who helped to oversee the assessment. “Candu expects to be able to complete the disposition within 30 years, with its reactors functioning commercially within the reconfigured UK electricity market.

“Secondly, the Candu solution is a proven technology, as it builds on the company’s existing Generation III 700MWe nuclear power plants. The MOX fuel process has been demonstrated in testing, and Candu has a robust track record of on-schedule and on-budget delivery of newbuild projects.

“Going forward, from everything we have seen, the IMechE is positive about the potential for this technology.”

The distinguishing feature of the Candu technology is the use of heavy water as a moderator that provides enhanced neutron efficiency, allowing for fuel flexibility. As a result, there are four distinct applications available or under development: natural uranium, recovered uranium, thorium and mixed-oxide fuel. It’s the MOX option that

offers potential for the UK’s plutonium problem.

To achieve lifecycle management, Candu would deploy its proprietary Canmox process, in which plutonium and depleted uranium powder feedstock are combined into pellets to produce a fuel bundle that would be irradiated in new reactors. This approach would dilute, reuse and reduce the stockpile, safely and cost-effectively.

The reactor would be based on Candu’s Generation III 700MWe nuclear power plants, which are used around the world. The Enhanced Candu 6 (EC6) would be adapted to advanced fuel and MOX duty, with four reactors being built to provide 2.8GWe of baseload power for UK markets.

It is envisaged that significant parts of the project would be located near the Sellafield site. Certain characteristics of the EC6 reactor make it suitable for more localised supply chains. Instead of featuring a large pressure vessel, as typically seen in pressurised water reactors, the EC6 uses pressure tubes, which are easier to fabricate, says the firm. Only a few global suppliers are qualified to produce large pressure vessels, whereas pressure tubes can be more easily sourced.

Michael Soulard, EC6 project director for Candu, says the £12 billion Canmox proposal would feature extensive use of local supply chains. “We are committed to localised production,” he says. “Indeed, up to 80% of a reactor could be made by the local supply chain.”

According to Candu, EC6 reactors could create 12,000 direct and supply chain jobs during construction, and a further 1,500 to 2,000 full-time operational staff posts. This job-creation potential is another factor that makes the Candu solution interesting, says Fox. “It provides opportunities to develop engineering skills and knowledge. We see this as an opportunity for the supply base, with potential for exports.”

In terms of design, the EC6 provides a series of inherent and engineered defences to prevent accidents and to provide accident protection. It incorporates two passive shutdown systems that are physically and functionally independent of each other. The safety systems ensure reactor shutdown, remove decay heat and prevent radioactive releases during events and accidents.

The traditional emergency water supply system has been upgraded to become an enhanced emergency heat removal system, operating as an alternate heat sink for residual decay heat following postulated low-probability accidents that render normal heat sinks unavailable. High degrees of redundancy within systems ensure that safety functions can be carried out.

The Candu reactor design also has inherent safety features as defences against severe accidents. A cool and low-pressure moderator provides a passive heat sink to absorb decay heat from the fuel for postulated conditions of so-called beyond design basis accidents. A large volume of water contained in the calandria vault that surrounds the reactor core provides a second passive heat sink, and can further slow down or arrest severe core damage progression.

Furthermore, the design provides a dedicated severe accident recovery and heat removal system to minimise the risks of severe accidents. This system, which includes gravity-driven, passive water supply lines and a pump-driven recovery circuit, is designed to arrest and contain any severe core damage within the calandria vessel and ensure containment integrity is maintained after a beyond design basis accident. For physical protection, the design encompasses all required responses to common mode events, such as fires, aircraft crashes and internal and external threats.

“The whole proposal has been well considered,” says Fox. “It is exciting to see a well thought through engineering option, which has been developed ‘under the radar’, emerge.”

The NDA has spent the past few months reviewing the potential of plutonium reuse in a Candu reactor. A position paper issued last year described the company’s solution as “clearly credible”. Overall implementation to first irradiation is predicted to be around 10-12 years, with reactors running on Canmox fuel for 30 years, providing low-carbon electricity to UK markets.

Discussions between Candu and the decommissioning authority continue, and a decision on whether to further progress the technology is expected by the end of the year.

Nuclear systems

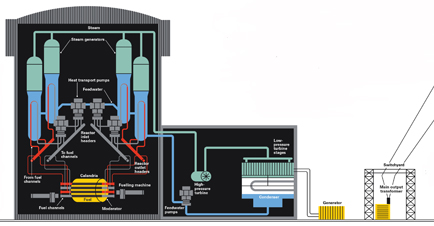

The EC6 nuclear systems comprise:

• A heat transport system with reactor coolant, four steam generators, four heat transport pumps, four reactor outlet headers, and four reactor inlet headers. This configuration is standard on all Candu 6 reactors.

• A heavy water moderator system.

• A reactor assembly that consists of a calandria installed in a concrete vault.

• A fuel handling system that consists of two fuelling machine heads, each mounted on a fuelling machine bridge that is supported by columns, which are located at each end of the reactor.

• Two independent shutdown systems, emergency core cooling system, containment system, emergency heat removal system and associated safety support systems.

Principal technologies for the EC6 reactor

Heat transport pumps

The EC6 reactor heat transport pumps retain the Candu 6 mechanical multi-seal design, which allows for their easy replacement. The heat transport pumps circulate reactor coolant through the fuel bundles in the reactor’s fuel channels and through the steam generators. Electric motors drive the pumps. The cooling of the pump seals lengthens service life and the time that the pump will operate under accident conditions.

Moderator system

The moderator of the EC6 reactor is a low-pressure and low-temperature system. It is independent of the heat transport system. The moderator system consists of pumps and heat exchangers that circulate the heavy water moderator through the calandria, and remove the heat that is generated during reactor operation. The heavy water acts as both a moderator and a reflector for the neutron flux in the reactor core.

The moderator slows down neutrons emitted from the fission chain reaction, to increase the chances of them hitting another atom and causing further fission reactions. The reflector is the material layer around the reactor core that scatters neutrons and reflects them back into the core.

The moderator system fulfils a safety function that is unique to Candu. It also serves as a back-up heat sink for absorbing the heat from the reactor core in the event of loss of fuel cooling – failure of the heat transport system to mitigate core damage. An added safety improvement in the EC6 is a connection to the elevated water tank that provides additional passive gravity-fed cooling water to the calandria. This connection extends core cooling and delays severe accident event progression.

Heat transport system

The EC6 heat transport system circulates pressurised heavy water coolant through the reactor fuel channels to remove heat produced by the nuclear fission chain reaction in the reactor core. The heated coolant is circulated through the steam generators to produce steam that drives the turbine generator system.

The heat transport system consists of 380 horizontal fuel channels with associated corrosion-resistant feeders, four reactor inlet headers, four reactor outlet headers, four steam generators, four electrically driven heat transport pumps, and interconnecting piping and valves arranged in a two-loop, figure-of-eight configuration. The headers, steam generators and pumps

are all located above the reactor.

Steam generators

The EC6 steam generators are similar to those of the Candu 6. The tubing is made of Incoloy-800. The light water inside the steam generators, at a lower pressure than the hot heavy water reactor coolant, is converted into steam. Steam wetness, which is the ratio of vapour/liquid concentration in the steam, is reduced at the steam nozzle using steam separator technology, resulting in improved turbine cycle economics

The nuclear timebomb

The Nuclear Decommissioning Authority is working with the Department of Energy and Climate Change to assess options for the reuse of separated plutonium.

As well as the Candu Canmox proposal, two other approaches are being evaluated:

• Examining in more detail the implementation of reuse of MOX in light water reactors. However, owing to the relative immaturity of the UK newbuild programme, the appetite of developers to include MOX in their considerations remains uncertain.

• Reuse in a General Electric Hitachi Prism fast reactor. This approach would see the conversion of separated plutonium oxide to a sodium-bonded U/Pu/Zr metal fuel using direct electrolytic reduction, pyroprocessing and metal casting techniques. Irradiation of this metal fuel in a Prism reactor takes place through a burn, rather than breed, mode. The Prism reactor is undergoing technical assessment.

Non-reuse is also being considered. Options here include long-term storage of plutonium, or immobilisation followed by disposal using hot isostatic pressing.