Articles

Answer: the energy required in railway operations and, inevitably, the associated climate-change impact.

In this article, we look at factors that affect the energy consumption of the railway but, for once, we are not interested in the energy associated with pulling, pushing and braking trains. Instead, we look at an aspect of railway operations that is often forgotten.

Twenty to 30 years ago, few public transport users expected air conditioning. Today, passengers expect high levels of comfort in trams, metros and mainline railway vehicles, even in Britain’s temperate climate.

Unfortunately, though, air conditioning does not only add to the first cost of a train and to the cost of its maintenance, it also adds to the mass of the train and its energy consumption. In addition, passengers also expect power for their electronic devices, wi-fi and, potentially, an entertainment system.

Hotel power

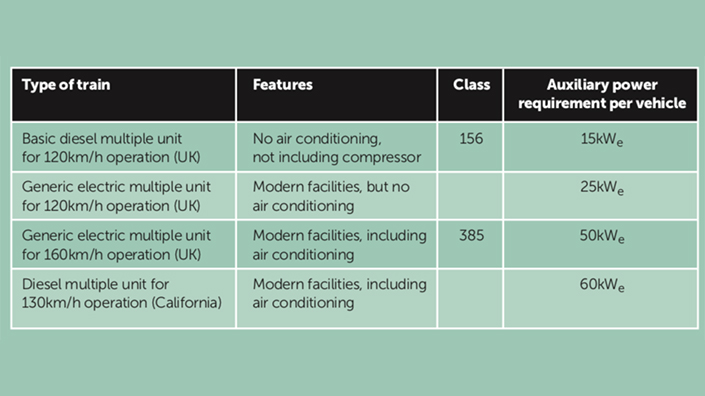

‘Basic’ trains, without air conditioning, require 15-25kWe of auxiliary or hotel power

per vehicle. Scotrail’s modern class 385 train, in the four-car configuration, musters 1,000kW of traction power with its four 250kW tandem traction motors and, on top of this, 320kVA for the auxiliaries. This represents 200kWe (kW electric) of hotel power on an average day (see table), adding some 20% to the overall power requirement of the train.

The value would be very different in Scotland in winter and any day of the year in Saudi Arabia... it is affected by the ambient temperature, where extremes are extending due to climate change, the number of passengers, the colouring of the roof of the train, whether solar- control glass is used and, to a lesser extent, the colour of the train chosen by the branding agency. Each passenger produces about 100W of heat that is combined with water vapour. Removing 15kW of heat from a full metro carriage requires additional energy.

A dark roof increases the need for air conditioning in summer but it is chosen because it makes for easier cleaning. Solar-control glass reduces the need for cooling but upsets mobile phone users. Dark colours appear to be favoured by branding agencies but they too increase air-conditioning energy use. There are many issues to be considered when trying to make a railway more environmentally acceptable!

Little extra capacity

A diesel train generates the auxiliary power on-board, either in the locomotive or, in the case of a multiple unit, by means of the power pack underneath the vehicles. A tank of diesel can accommodate this requirement for auxiliary power easily but battery- and hydrogen-powered trains have little in terms of extra capacity.

There is a general belief that there are no such constraints for electric trains supplied by overhead or third rail. However, the energy still has to be produced and transmitted.

This is where railways meet further complications: the Swiss railway network operates with a Taktfahrplan where trains reach major nodes just before the hour and leave just after the hour. Therefore, large numbers of trains accelerate at the same time, resulting in high short-term power demand.

Swiss Federal Railways (SBB) is a producer and consumer of electricity and has implemented a smart-grid approach for its energy supply network. Thanks to this, the company has been able to introduce load-shedding.

SBB is doing this in two stages, with the intention of reducing peak loads and to avoid infrastructure upgrades to deal with the peak load in the 10 minutes where so many trains depart from the nodes. As a first stage, they use the data infrastructure and radio communications to switch off train heating and air conditioning. In a second stage, SBB expects to control the rates of acceleration.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.