Articles

Some earlier concepts reflected the military hardware of the time – namely artillery. The influential 1902 French short film Le Voyage dans la Lune shows a spacecraft being launched to the Moon by a large cannon, for example.

Despite the truly unprecedented advances in rocket technology that came later in the century, the idea of shooting vehicles into the upper atmosphere and beyond was still appealing to the US and Canada in the 1960s, as they fired projectiles to altitudes of up to 179km at speeds of Mach 6 in the High Altitude Research Project (Harp). The approach overcame one of the biggest obstacles to economical rocket-based space launches – the ‘tyranny of the rocket equation’, whereby the required amount of propellant increases exponentially with the increase in the rate of change of velocity.

Considering the limits of conventional rocket launches, with the huge structures and massive weights involved, aerospace entrepreneur Jonathan Yaney looked to the Harp project for inspiration. Then came the thought – instead of firing them, why not spin rockets up to speed?

Spinning out

Just eight years after Yaney founded SpinLaunch, the company has made significant progress towards that goal. First, it broke the world record for the fastest rotational object, using its spinning hardware. Then, on 22 October 2021, it successfully tested its Suborbital Accelerator at Spaceport America in New Mexico, launching a reusable flight vehicle upwards at supersonic speeds, before later recovering it.

SpinLaunch has some bold ambitions. It claims that the velocity boost from the L100 Orbital Mass Accelerator’s electric drive will result in a four times reduction in fuel required to reach orbit, with a 10 times reduction in cost, and the ability to launch several times a day.

“Right now, the lowest-cost launch vehicle to put a small satellite into orbit is about $7m,” says Yaney in a SpinLaunch video. “SpinLaunch is bringing that cost down to below $0.5m.”

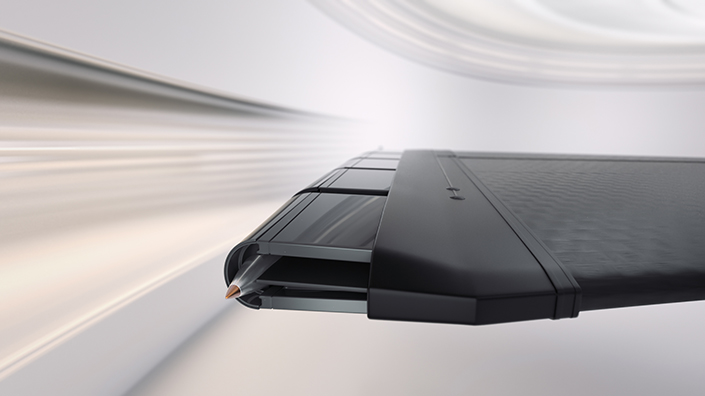

Both the suborbital and orbital accelerator, which could provide customer launches by 2024, work in the same way. A launch vehicle, with a carbon-fibre shell and heat-resistant tip, is loaded on to the end of a ‘tether’, also made of high-strength carbon fibre. The large cylindrical vacuum chamber is depressurised, before an electric drive begins to spin the arm. Unburdened by aerodynamic resistance, the vehicle is accelerated up to nearly 5,000mph (8,000km/h), before it is flung upwards through an exit tunnel, heading towards space.

A computer-generated image of a vehicle being spun before launch (Credit: SpinLaunch)

Once it has passed through the atmosphere, the outer shell falls away and conventional rocket stages take over, delivering satellites weighing up to 200kg to the desired location in low Earth orbit.

Ruggedisation

The technique, and supporting technology, are radically different from previous rocket launches, and inevitably face some challenges. The initial 200kg payload limit with the L100 is much lower than the average weight of conventional satellites, for example, although combined with a rapid deployment capability it should be sufficient for the company’s target market of small satellite constellations.

Satellites themselves will need some ‘ruggedisation’ to withstand the extreme g-forces of the kinetic launch system, but SpinLaunch engineers are already testing and qualifying components, and they believe that standard materials and processes will be suitable. The company is developing a range of efficient satellite chassis, with just a small mass increase compared to conventional spacecraft.

The firm’s claims of zero-emission launches will also depend on using low-carbon energy to spin up the kinetic launch systems. But, for every challenge, SpinLaunch seems to have a solution. Accessing space has never been easy, and a lack of imagination is more of a burden than 14-storey fuel tanks ever were.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.