The University of Liverpool Velocipede Team (ULV Team) is currently testing the aerodynamics of the ARION1, selecting a rider and establishing further industry links, as the velocipede speeds through its development.

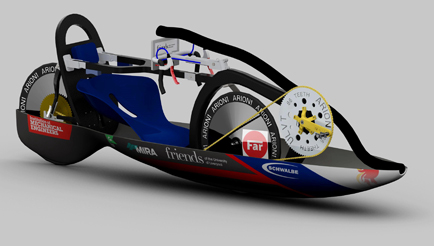

The ARION1 is essentially a bicycle, although it’s hard to tell from the outside. It has two wheels, a set of pedals, a seat, handle bars and many other components that are found on an everyday bicycle. One of the key differences is that the ARION1 is entirely encased in an aerodynamic shell or ‘fairing’, designed to cut through the air.

When the ARION1 reaches speeds beyond 20 miles per hour, aerodynamic drag (or wind resistance) accounts for over 80% of the total drag of the vehicle. Reducing the amount of aerodynamic drag is essential, because this human powered vehicle has an intended speed of up to 90 mph.

Entering the World Human Powered Speed Challenge at Battle Mountain, Nevada in September 2015, ULV Team aims to break the world record for the fastest human powered vehicle, currently 83.13 mph, which was set in September 2013 by TU Delft and VU Amsterdam universities.

ULV Team is gathering publicity and support from the Institution; it has been offered use of the aerodynamic testing facilities at MIRA, and the expertise of a range of industrial partners, including Far Composites, which is working with the team on the design. It is on course to have manufactured and tested a wind tunnel model by October this year. Months of computational fluid dynamics (CFD) testing will come together with the opportunity to assess the aerodynamic performance of the ARION1’s shell in real life, as team leader, Ben Hogan, explains:

“Aerodynamics plays a great part in getting the design of the ARION1 right. We need to get the air flow working perfectly, and minimise drag. MIRA’s loan of its wind tunnels in September is so helpful and we are very grateful. We have carried out extensive aerodynamic computer modelling using the University of Liverpool’s High Performance Computing facilities, which allows us to analyse the air flow, using millions of calculations which require far more power than a standard desktop computer. What we are aiming to achieve at MIRA is a validation of our computer modelling, using real wind tunnel results.”

One of the most striking aspects of the endeavour is the appearance of the carbon fibre composite shell encasing the bike. Ben continues:

“We need the ARION1 to cut through the air. The way to minimise drag is to make a super-streamlined shape. Birds, when they dive to catch prey, adopt a pellet – or capsule – shape, which is what is replicated in our velocipede shell. Its form keeps the airflow nice and smooth. It’s similar to the design of an aircraft’s wing, which resembles a teardrop shape – thicker at front, tailing off to a point. It looks a little strange – in fact it’s a great talking point – but it does offer significant aerodynamic benefits.”

Ben says that there is much heated discussion within the design team about which is the most technically difficult area. However, Ben feels that aerodynamics has a large effect on the design:

“Any decision made about the design of the ARION1 has to run through aerodynamics testing, and if the findings show detrimental effects on the aerodynamic performance then, harsh as it may be, we have to say no: we cannot sacrifice one jot of the performance capability.”

Financial considerations are another aspect of the project that the team cannot afford to shy away from:

“We are continually refining the design using CFD before we validate at MIRA. This is, at its heart, an optimization project. The ARION1 has over 100 components, and it’s essential that we hone them to the lightest and sleekest that we can, using high-performance materials. Naturally, these don’t come cheap.”

“Designing a vehicle at the cutting edge of engineering comes at a price, and a vast amount of our time and energy goes into contacting suppliers, manufacturers and other sources of resource and funding to keep the project moving, and keep the engineering ambition on track.”

The ARION1 could be up to 40 times more aerodynamic than a Bugatti Veyron, with a top speed of 90mph on the world’s smoothest road, generated entirely by pedal power. The velocipede will be designed, manufactured and ready to race by May 2015, and will attempt the record in September 2015.

In addition to the support of the Institution and MIRA, a number of other companies are helping the team work towards its goal. A current list of

sponsors is available on the team’s website, where

companies can also enquire about coming on board.

Ben says: “When we heard about the 2013 World Human Powered Speed Challenge, we couldn’t get the speed achievement out of our minds. In 2015, we will be the first UK university team to attempt this record. We are all Affiliate members of the Institution, in our third year of study at the University of Liverpool, and the ARION1 is our group project. What gives us confidence is that we have one of the largest and best equipped laboratories in the whole of Europe at the university; we undertake pioneering studies in aerodynamic analysis and the university has great industry connections, not to mention top academic support. There is also, currently, a huge appetite for professional cycling, which really works in our favour.”

He adds: “We are inspired by projects such as

Bloodhound SSC, from its engineering ambition to its global educational reach. We want to combine a fantastic technical challenge with the human endeavour it will take to complete it. ARION1 is a perfect match of engineering refinement and physical endurance.”

The ULV Team has teamed up with sport scientists from another University. They will help recruit two male and two female riders and train them under a specially devised year-long training programme.

Potential riders should apply via the ULV Team’s website. The engineering and human elements of the endeavour are finely balanced. ULV Team’s partner, yet to be named, has the capability to assess and analyse cyclists using cutting edge facilities, to match the engineering expertise that the University of Liverpool will deliver. The rider will be just five inches from the floor and will need to generate over 700 watts of pure human power.

A successful relationship between the students, the Institution, and the engineering industry is vital to keeping the project on target. Ben finds that the Institution’s extensive network, its heritage, and its involvement in high-profile endeavours such as Formula Student and Bloodhound, make it the natural home of resources for the team:

“We are able to show manufacturing partners and those working with us in many aspects of the challenge that we are part of the Institution, too. We have a great Formula Student team at the University of Liverpool, and when they heard what we were doing they immediately suggested we make the Institution aware.”

“The Institution, with its heritage, is like a library and an address book combined, and sometimes it reminds me of ‘The A Team’: people at the Institution are so supportive, linking ULV Team with ideas, contacts and expert advice.”

Like teams participating in Formula Student, ULV Team fully recognises that an enormous part of its challenge is to excite and involve industry, in order to get the vehicle developed, tested, manufactured and transported to Nevada next September. Ben says they need to develop more links with industry, and is also keen to use the velocipede to raise the profile of engineering in schools and engineering fairs:

“We are exhibiting on the Special Features stand at the

Advanced Engineering Show at the NEC in Birmingham, 11-12 November, where we are going to be showing our full size display model, for the first time. The Institution put us in touch with a fantastic industrial partner who is working with us to manufacture our 2.5 metre long display model; it will really enhance our ability to get the message out there.”

“We want to use our challenge to raise the profile of engineering. We have been working on student recruitment on behalf of the university, and we are keen to follow in the great footsteps of Bloodhound, in terms of its educational reach. The amazing achievement potential of our vehicle – aerodynamic design in partnership with human power – is inspiring for children and students across the world.”

Ben and the team are keen to work with organisations who are inspired by the ARION1 project, and happy to discuss the project further to find ways to link with industry and with education.

Ben concludes: “The team and I have been overwhelmed by the positive response we have received since the early stages of our journey. There is now just over a year to go. We are extremely excited about attending the September 2015 event in Nevada, and having the opportunity to showcase the UK’s innovation for sustainable transport on an international stage.”

Apply here to be the rider of the ARION1 Find out how your organisation can support ULV Team Follow the team on twitter @ULVTeam