Engineering news

Researchers from Germany and Switzerland have won a €50,000 EU Fusion Innovation Prize for the development of a ceramic and copper cable that can carry up to 100 times more current than conventional, uncooled, cables.

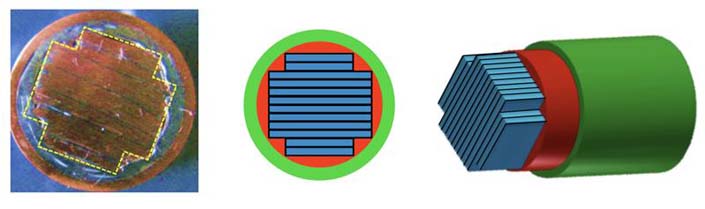

The “cross conductor”, or CroCo, uses a superconducting ceramic material shaped like a cross inside a copper cable.

According to researchers from the Institute for Technical Physics at the Karlsruhe Institute of Technology (KIT), Germany, CroCo cables could form a basic part of future nuclear fusion power plants, industrial facilities, or DC power grids.

Dr. Walter Fietz from KIT, said: “Our novel conductor design with a cross-shaped cross section can efficiently transport more current than comparable cables and it is very easy to produce. This EU prize for our concept illustrates its high application potential.”

High-temperature superconductors are ceramic materials that can transport current, resistance-free, at temperatures typically around minus 200 degrees Celsius. However, long lengths can only be produced as micrometer-thin coatings on metal tapes.

(Credit: Karlsruhe Institute of Technology)

The CroCo consists of two different widths of high-temperature superconducting tapes stacked and soldered over their full length, to form a cross. The tapes are slightly twisted to optimise the magnetic properties of the conductor. The conductor is packed into a copper tube, and the gaps between the cross and the tube filled with solder.

Fietz said: “In this way, the flat, tape-shaped superconductor is used to build a round cable, the shape of which facilitates further processing with standard processes.”

In fusion power plants, such as the ITER reactor being built in Cadarache, France, high-current cables for currents of up to 68,000 Ampere will be required to supply power to the superconducting coils generating the plasma-confining magnetic field.

Cables with a current-carrying capacity of 10,000 to more than 100,000 Ampere DC are also needed for energy-intensive industries, such as aluminium smelters, datacentres, electrolytic deposition of chemical elements, or energy production in offshore wind parks. Superconducting cables may also be used to establish direct voltage grids for transmitting renewable energies from the producer to the consumer without any losses in the future.

The original idea to wrap flat, superconducting tapes in copper to form a cylinder was developed by the Swiss Plasma Center and further developed by Fietz and Dr. Michael Wolf from KIT.

A patent application for the prototype production facility to continuously produce CroCo conductors has been filed.