Whether you are focussing on keeping a safe distance between co-workers, eliminating travel between sites or just trying to carry on producing vital supplies while key personnel are self-isolating, having the right tools for the job eases the strain for everyone involved.

In a nutshell, the TH LINKs for PROFIBUS and PROFINET provide access to network-specific issue monitoring. TH SCOPE allows data from multiple sites and networks to be collated into one interface for easy management. By accessing this data via a VPN, this can then be analysed and responded to from anywhere in the world. Should local teams be low on manpower, advice and assistance can be relied on when it is needed most - from anywhere in the world.

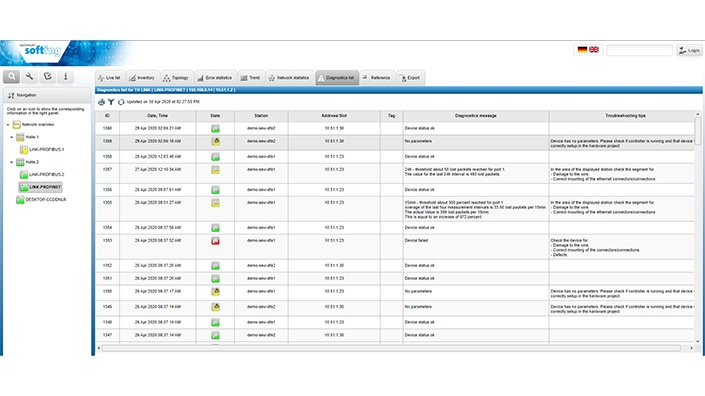

TH LINK is a monitoring tool that sits on the PROFIBUS and Ethernet networks. It will send an alert both when there is a problem and before the problem occurs by looking at patterns in the error messages and spotting trends. Each TH Link has its own webserver built-in for independent use and access but can also be connected to TH SCOPE to add additional features and gather data from multiple TH LINKS, either PROFIBUS or PROFINET.

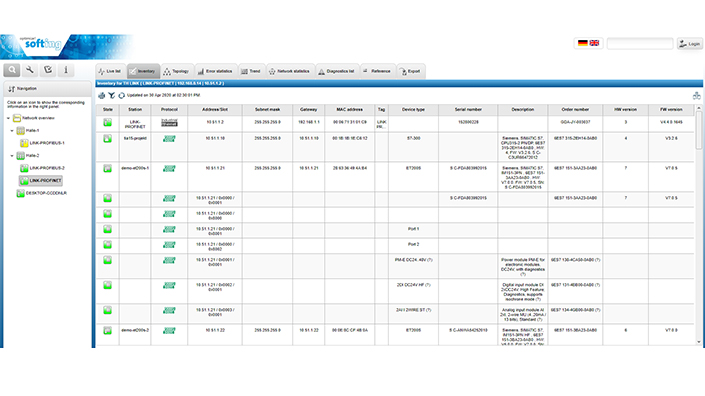

TH LINK PROFINET delivers an integrated software solution for continuous status monitoring and predictive maintenance, as well as ongoing measurements, network load diagnostics, fault identification and fault location pinpointing during disruptions. As part of this process, it records the relevant data in the IP networks for up to 253 participants and makes these available to the user via TH SCOPE. The module can be integrated into both the existing machine pool and into new equipment simply by adding it to a spare network port and giving it an IP address, then telling the TH LINK what range to monitor.

TH LINK PROFINET will also see non PROFINET devices connected to the network. If these are compatible Industrial Ethernet devices, such as vision system cameras, Ethernet IP or Modbus TCP, then diagnostic information for these will also be available.

TH LINK Industrial Ethernet is functionally very similar to the TH LINK PROFINET but is designed to also support Ethernet IP and Modbus TCP. However, these networks have lower levels of diagnostic information available compared to PROFINET, so some features are not available.

TH LINK PC is essentially the same software as the TH LINK Industrial Ethernet but running on a Windows platform. If there is already an industrial PC installed on the network then this removes the need, and therefore cost, of the TH LINK hardware.

TH LINK PROFIBUS allows users to remotely access and monitor a PROFIBUS network. As well as allowing staff to view current network utilisation, it also presents a comprehensive inventory of network components, trends on what devices are experiencing, and diagnostic issues. It can also act as a class 2 master or a remote gateway for calibrating or altering settings in devices connected to the network over ethernet.

TH SCOPE is aimed at machine operators and maintenance personnel. Together with the TH LINK components, the product supports all commonly used network protocols in addition to PROFINET. It can be flexibly integrated into existing systems and processes and is very easy to use meaning that no specialised network knowledge is required and offers both stationary and mobile access.

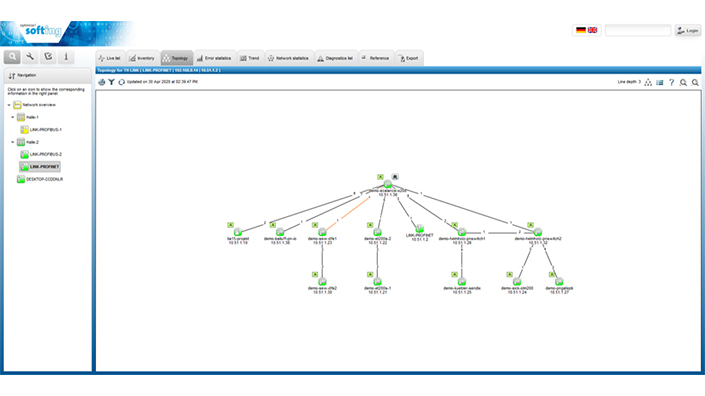

With the additional power that a “server” brings with the TH SCOPE software, it is possible to perform additional statistical analysis, create graphical topology maps (PROFINET) and compare the current setup against previous configurations. This is particularly helpful if you build a complex machine, dismantle it and ship it around the world before reassembly onsite as you can test before and after installation to ensure that the rebuild has been done correctly.

The software can be installed either onto a real or a virtual machine (VM). A common factory set-up example is to install TH SCOPE on a standard PC in the maintenance office as it does not require expensive server hardware. The implementation, parameterisation and commissioning of TH SCOPE and TH LINK is fast to install and deploy. It takes approximately 30 minutes to install the software and 10 minutes configuration for each TH LINK. The benefits include constant, web-based monitoring including an alarm system and consistent availability across different protocols.

One of the major benefits of TH SCOPE is that several fieldbus networks and communication protocols can be monitored at the same time using just one application. In the event of faults, the user is automatically sent advice on how to eliminate the fault. Furthermore, the network status can also be used as a reference for future comparisons. Additional TH LINKs can also be implemented to monitor the entire network and actively safeguard against downtime.

These products can be used in all manner of industrial environments, from chemical and food and drink processing to automotive assembly lines. In one use-case within a major car manufacturing plant, TH LINK PROFINET and TH SCOPE products provide support by ensuring consistent high-quality communication for network acceptance testing and during normal operation. Due to the straightforward and rapid identification of error causes after the detection of erratic behaviour, a constantly higher availability of the facilities is achieved. The ability to connect an entire network including its subnetworks by means of a single TH LINK PROFINET device contributes to a fantastic return on investment. Another major advantage is the option to retrofit existing facilities without stopping normal operation.

It is worth noting that the TH LINK for PROFINET is an active device on the network. This is due to the functionality of the switches, otherwise packets would be directed directly to the Controller and never be seen in a diagnostic device without a mirror port. The TH LINK PROFINET is entirely passive unless you enter a password to enable the Class 2 master functions, as all PROFIBUS packets are available everywhere on a functional network.

In combination with TH SCOPE, TH LINK for PROFINET can deliver network condition reports, current installed topology drawings (as opposed to the original design install drawings), diagnostic information and a complete inventory of devices/device names, serial numbers and order numbers.

With global disruption and remote working becoming increasingly widespread during the Covid-19 pandemic, the ability to “keep calm and carry on” is vital. The TH suite of products provide a unique armoury which enable exactly that – business as (un)usual is the new normal and by coping during the toughest challenges, manufacturing facilities will be able to move forwards again with improved, streamlined operations into the future.

https://www2.hitex.com/remotehealthandhappiness

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.