Institution news

Deployed as the Long-Range Reconnaissance Group along with REME soldiers from 2 Scots LAD, 29 Engineer Regiment LAD and 32 Regiment Royal Artillery LAD, the experienced engineers and technicians were in theatre from November 2022 to June 2023. Scott explains the challenges and rewards of repairing and maintaining equipment across arduous terrain.

IMechE: What is the role you are playing out there?

Scott:

The LADs role in Mali was to support the wider British Army's Operational Task Group by virtue of maintaining and repairing its equipment. To provide context, the country has struggled with mass protests over corruption, electoral probity, and a jihadist insurgency in recent years. This has made much of the north and east of the Sahel region ungovernable and extremely dangerous; driving the United Nations to intervene. As a highly skilled and close-knit forward engineering team, we deploy alongside infantry and reconnaissance soldiers to support the equipment of the British Army's Long Range Reconnaissance Group (LRRG) which represents the UK's contribution to the United Nations Multi-Dimensional Integrated Stabilisation Mission in Mali (MINUSMA).

The team is made up of Vehicle Mechanics, Electronics Technicians and Recovery Mechanics. They have spent five months in the Sahel Desert after three months of intensive validation training. They have the difficult job of ensuring 104 Armoured and Protected Mobility Vehicles, over 600 associated weapons system, and a multitude of optronics and communications systems are in A1 condition to enable high intensity cross country desert manoeuvre throughout some of the world’s most challenging terrain. In terms of impact, MINUSMA has been focused on tackling the growth of terrorist violence and conflict between communities in the LRRG’s vast area of operations. It is easy to recognise the critical role the LAD has had in enabling the Task Group to stay moving and able to protect itself, in both day and night conditions.

IMechE: How are your engineering skills called on and what kind of projects or tasks do you take on?

Scott:

Within the LAD and Fitter sections our engineering skills are used every day to provide forward repair. Periodic maintenance, mandatory inspections, diagnostic checks, and complex repairs such as Main Engine and Major Assembly changes are also routine. Concurrent to day-to-day business, we have been working on engineering projects to enhance the effectiveness and efficiency of the unit through potential modifications. Some of the capability development and innovation that the LAD has pushed through will drive whole force improvements across several areas. The examples are wide ranging. Through the leadership of the Artificer Senior Non-Commissioned Officer, the team have ensured a 100 percent reduction in 'Grey Data' across its Operational fleet.

The team’s work streamlining information available on the Army's Joint asset management tool has ensured organisational overview of repair timelines for UK Commanders. This has affected the prioritisation of materiel for dispatch to Mali via the Logistics Chain for the better. Innovation has been key due to our dislocation and the LAD have also worked extremely hard to develop additional vehicle Lifting and Recovery Policy and this has been used to amend Self and Peer Recovery Standard Operating Instructions across Defence. We also have a responsibility as professional engineers to enthuse a better Equipment Care culture across the Task Group user community. Indeed, the team’s ability to influence, inform and empathise with phenomenally professionally written briefing notes, correspondence, training, and presentations, is founded in the hard-won credibility they have earned 'on the ground'. The end state has been improved operational effectiveness.

IMechE: How do issues such as distance from the UK, availability of spares, equipment, and workshop facilities impact on your work?

Scott:

The workshop in theatre is very well established. It has three bays outside which importantly, provide shade and hard standing. For the more complex and attritive tasks, we have an air-conditioned hangar which has an additional three bays and houses our level 3 repair facilities for optronic and aerial vehicles. The workshop is equipped with all the infrastructure and intra equipment required to conduct the maintenance and repairs tasks already highlighted. This includes jacks, axle stands and the Special Tools and Test Equipment (STTE) concurrent to maintain the 15 vehicle types across the spectrum of the Task Group. Each member of the LAD has access to issued tooling, but most own their own tools due to the outdated tooling issued.

When deployed in the desert on patrol, the LAD can provide most of the capability we can in camp, albeit we use vehicles to lift equipment and deploy with manual, rather than automated tooling. Space is at a premium so we can only deploy with limited tooling and spares. We need to be very considerate about what we deploy with and what we leave behind, although we did have access to helicopters for spares at intermittent periods. Providing this essential equipment support when deployed is our raison d’etre - ensuring that the LRRG can accomplish their mission depends on it. In all honesty, the availability of spares has been outstanding on this operation. Far more impressive than timelines back in the UK. This is due to the high priority nature of provisioning. The spares and planning team at SCOTS DG, working in cooperation with the RAF and our teams back in the UK, have been second to none.

IMechE: How does the weather and other conditions impact on the equipment and the personnel?

Scott:

The weather can reach temperatures of +40° on some days and it has certainly taken its toll on both personnel and equipment. On arrival into theatre, we all conducted a mandatory acclimatisation programme, which enabled us to gradually adjust to the heat but when deployed on patrol in the desert, the heat was relentless, and you would need to make or find shade.

We would operate the vehicles during the cooler hours of the day to mitigate overheating, but it would inevitably happen to some vehicles.

IMechE: What have you most enjoyed as an engineering challenge?

Scott:

Most days on operations offer engineering challenges – that is why we joined the REME. These challenges are exacerbated on the ground in the desert while conducting high intensity cross country manoeuvre. Unlike civilian engineers, we have no choice but to enable vehicle movement – to fail equates to mission failure and REME soldiers are qualified to conduct safe expedient maintenance and repair. These situations are when the LAD earns its money. All our people are highly qualified and competent at trade. They have expert knowledge and a particularly good understanding of how the vehicles work, would conduct repairs tenaciously with either parts which we had at hand or intuitively conducting authorised expedient repairs to keep the patrol moving. In barracks, the LAD have led with engineering innovation to enhance the effectiveness and efficiency of the LRRG through engineering projects. One will potentially increase the distance at which the unit can operate via communications, another will reduce the time it takes to conduct a complex repair through modification if endorsed. As a Fitter Section Commander, it is difficult to pinpoint the most enjoyable engineering challenge as we meet new challenges every day, but the most rewarding part of the job is offering advice, mentoring other team members, seeing a repair completed and the vehicle being operationally fit.

IMechE: What have you most enjoyed from a personal perspective?

Scott:

From a professional personal perspective, being a Fitter Section Commander and having the privilege of leading a high calibre team on operations is the pinnacle of every Artificer’s career. One of the best parts of the job is being on the tools diagnosing and repairing faults with the opportunity to develop and mentor the team. I also enjoy the pressure and responsibility of making critical engineering decisions to ensure the maximum vehicle availability to contribute to mission success.

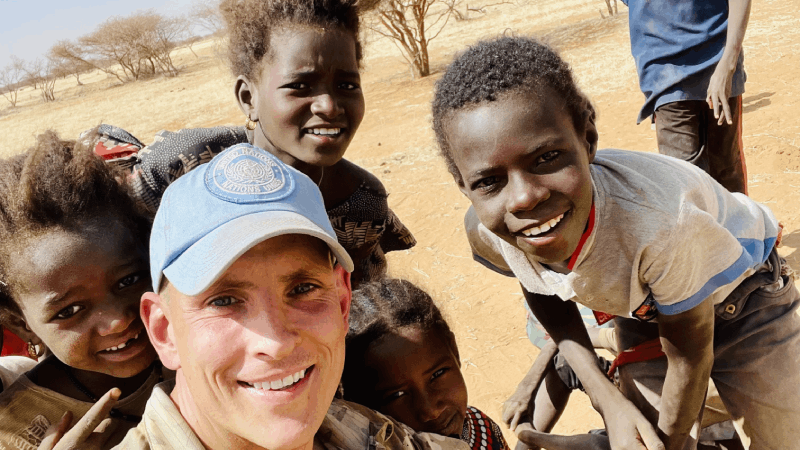

The opportunity to make a small difference to the lives of the people we met on patrol was extremely humbling and rewarding. Small things like being able to offer some food and water those that need it most and providing protection to villages that really needed it will live with me forever. One of the most rewarding instances was when we played games with the children we met while on patrol and seeing them having fun and smiling, a noticeably short respite from the hardships they live daily.