You had a glittering career as an engineer. How did that lead to your involvement in land-speed record bids?

After I’d retired in the early 1990s, I started volunteering at the Brooklands motorsport and aviation museum in Surrey. When I went into the archives there, I came across a huge wall of wind-tunnel reports for Vickers and other aircraft-makers, going back to the early 1930s and before. As a qualified aerodynamicist, seeing that amount of historical data, well, it was like being in a goldmine.

While cataloguing the material, I also found wind-tunnel data on cars that had been running around the Brooklands race track. This included material on all the land-speed record machines – Malcolm Campbell’s Bluebird cars, the Golden Arrow, the Silver Bullet, the Thunderbolt. They had all been wind-tunnel tested at Brooklands.

I found that the numbers didn’t stack up – the cars had underperformed relative to their original design specifications. My theoretical predictions made using that aerodynamic data showed that the cars should have gone faster. The discrepancy started at about 200mph, and the faster they went, the greater the discrepancy. I was at a loss to know why. That sparked my interest in land-speed records.

How did you get involved with Richard Noble on the Thrust SSC project?

I wanted to get more data to support my research. So I went to see Ken Norris, who had designed Donald Campbell’s Bluebird. I was late for the meeting and that meant I overlapped with Richard Noble, who was a personal friend of Ken. It was a pure chance encounter. When Richard heard that I specialised in high-speed aerodynamics I could see his mind working. And that was that.

What did you think of Noble’s plan to build a car capable of shattering the land-speed record?

When he told me he wanted to go supersonic, I said “don’t be ridiculous, it’s impossible, you will never keep the car on the ground”. But two or three months later, I got thinking – some of the reasons I gave for it being impossible weren’t strictly true. I had told him that shock waves forced under the car would lift up the nose, sending it straight up. But what if we really stuck the tail of the vehicle up in the air? I knew forces would push it down – so there had to be an angle at which it wouldn’t lift up because there would be a zero vertical force. On that logic, I knew it was conceivable that you could have a supersonic car that stayed on the ground. I telephoned Richard and admitted that what I’d told him wasn’t quite true. That was it – “right, we’ll do it then”, he said.

What were the biggest challenges?

I decided early on that the car would be better off with two jet engines rather than one. But then we had to work out how we were going to do that. Should we have the engines on top of each other? Maybe, but that would give stability problems. We played plenty of games like that.

I decided to put the engines side-by-side, but wanted to put them well forward. That introduced severe problems, because it meant the front wheels couldn’t be steered because they were outboard of all the structure. So we had to steer the rear wheels. That introduced other problems. Rear-wheel steering is theoretically unstable, partly because of the mathematics of it and partly because of physiology. When you turn to go left, your stomach goes right, and so you have to train yourself to overcome that.

We referred the matter to the late Professor David Crolla, vehicle dynamics expert at the University of Leeds, and we did a lot of research on rear-wheel steering. Eventually, we kind of made it work. But in truth, it was a close call in terms of whether it was good enough. It was a credit to Thrust SSC driver Andy Green, who has the most astonishing reflexes, ensuring the car stayed stable.

It sounds like you had to think laterally to overcome many technical difficulties. Was there ever a time on Thrust when you thought, privately, “this is crazy, it’s never going to work”?

Plenty of times I thought “This is crazy, we will never get the money to complete the project.” But I don’t think there was ever a time when I gave up on the technology. I always thought we’d make it work. But it was a trouble keeping the team together and keeping the sponsors behind us.

Thrust broke the land-speed record, achieving 763mph, and was the first car to go past the sound barrier. How did it feel when it all came together?

It was a mixture of relief, exultation and exhaustion. Myself and a few colleagues were positioned at the start of the course in the Black Rock Desert in Nevada, and when the car did its run we were left totally alone in the wide open space. When we realised it had achieved its goal, there was great exhilaration.

We drove the 14 miles to the finish line, and there we found the car surrounded by people. The desert had filled up – it was a scene of almost biblical proportions. There was our team, hundreds of press, people landing on the desert in light aircraft, people who had been parked up overlooking the event, crowds coming from everywhere. It was a scene of euphoric celebration. There were people wandering around in tears, saying “This is the greatest day of my life – I’ve seen history in the making.” At that point, you couldn’t fail to be excited.

You were also a prime figure on the JCB Dieselmax project, which achieved a land-speed record for a diesel vehicle. Presumably that presented a very different set of challenges from Thrust?

That was the first time I had been involved in a wheel-driven record attempt, as opposed to a jet-driven vehicle. It was a different art form. But actually, Dieselmax proved to be the point at which my museum work really came in useful.

From looking at why land-speed record cars had not achieved maximum speed, I had arrived at a theory: the cars kicked up so much dust and salt crystals, which was blasted over the rest of the vehicle, that they had suffered from “spray” drag. The rear wheels were

getting absolutely covered. That’s what I deduced was going on.

So when I started on Dieselmax, I said to the people on the design team that I wanted to do an experiment on the shape of the car. The weight of the engines meant the centre of gravity had to be low, meaning the car had to be very close to the ground. I looked at ways of channelling air more efficiently from under the car, avoiding the accumulation of salt crystals on the underside. Two channels were created, so that the air could get through and out again.

It worked well. Dieselmax was designed to reach around 350mph. But if the tyres had allowed it, we could have gone up to 380mph. I had proved my point – that with the right kind of design, the problem could be overcome.

Now you are involved in the Bloodhound project, which aims to build a car capable of travelling at speeds of more than 1,000mph. What was the starting point for designing such a vehicle?

When we finished Thrust, my immediate reaction was that we had done so much damage to the desert. Shock waves had penetrated the surface. When we looked afterwards at the measured mile for the full width of the car, it had become fluidised to the depth of 20cm. I could put my hand in and it felt like there was nothing there.

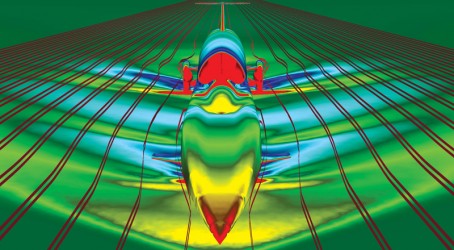

I remember thinking a huge amount of energy had gone into doing that. I felt that nobody else was going to beat Thrust’s record, because they were also going to come across this problem. Now I realise that’s not quite true. It’s possible to use computational fluid dynamics to design a vehicle that is shaped to minimise the pressures on the surface. That’s been a very important factor in the work we have been doing on Bloodhound SSC.

Where are you with the Bloodhound project now?

The shape of the car has been designed. I’m now confident it will stay on the ground, and that it is controllable. As far as I’m concerned, it meets all my requirements. I’m now acting as a service to other people on the project – on bits and pieces such as where we put the exhaust pipes on the auxiliary power unit. This is where my practical engineering skills come in.

Are you still worried by any aspect of the project?

One thing we have to prove is that we can stop in the distance available. On Thrust, we had a 20-mile track in the Black Rock Desert. But global warming means that is no longer available to us, because sand dunes have formed on it. Andy Green has been researching flat dry surfaces over the world, and we have whittled it down to Hakskeen Pan in South Africa, which is 12 miles long.

On the acceleration side, we have a rocket and jet engine that will allow us

to get to 1,000mph, but we’ve got to ensure we can stop. We have to make sure the air brakes are powerful and reliable enough.

How likely is it that the design of the car will enable it to reach 1,000mph?

With all the data I have now got – vehicle weight, vehicle drag, jet engine performance, rocket engine predicted performance – yes, we are online for 1,000mph. That doesn’t mean that we will achieve it, because there are all sorts of assumptions in there. But the assumptions are cautious. Overall, though, I think we can get to 1,000mph. But this is a first prototype vehicle – unique – all the engineering has to be proven on a step-by-step basis. At any stage, we could find a problem.

What will come out of the Bloodhound land-speed record attempt? Isn’t there a risk that initiatives such as this become vanity projects for those involved?

The main thing is the educational benefit – more than 5,000 schools in the UK are signed up for it. In the past year, there has been a 10% increase in the number of people studying maths at university. The press says it’s the Brian Cox effect. But Bloodhound has hundreds of ambassadors out there, so I’d like to think we’re having an effect, too.

The project is also a good example of design transparency. We’re publishing what we are doing on the Bloodhound website. If people say “we don’t agree with that”, then we say “tell us more”. We want people to be constructive. There are a lot of benefits in not waiting to publish under peer review to get people involved.

You’ve had some great experiences on these land-speed record bids. Have you ever had the desire to drive any of the cars you have helped design and build?

No. I know my limitations. I was an aeronautical engineer for many years, yet I never had the yearning to learn to fly. It’s not really my thing. I don’t think I have the necessary psycho-physical responses. Other people can do it better than I can. People such as Andy Green are unique – his ability to absorb data coming in from different channels at enormous rates, and to respond quickly, is incredible.

Top-secret role while the Cold War was at its coldest

Born in London in 1932, Ron Ayers forged a successful career as an engineer, originally as an aerodynamicist in the military and defence sector, before running a family printing-equipment firm for many years.

But he nearly missed his calling. “The school I went to didn’t think I was very bright, and didn’t think I should go to university,” he recalls.

Fortunately his talents were recognised by Handley Page, the aircraft-maker, which offered him the chance to become an apprentice. “Handley Page put me on its degree course, and I studied aeronautical engineering at what is now known as City University,” he says. “Taking a degree at the same time as doing an apprenticeship was hard work. There was no social life. But at the end, I was well equipped.”

Handley Page believed in giving its apprentices a high degree of responsibility, and Ayers soon found himself working on a top-secret project that was deemed crucial to national security. “It was the 1950s and the Cold War was at its coldest. Handley Page was developing the Victor bomber to carry the nation’s nuclear deterrent. I spent several months in the wind tunnel doing tests on the Victor. I also helped design the test rig for the bomber’s fuel system. It was exhilarating.

“To this day, I think it is very important to give young engineers responsibility at an early age. It reminds them that it’s not a game.”

After several years at Handley Page, Ayers moved on to the Bristol Aeroplane Company in its guided weapons division, became the chief aerodynamicist, and then later head of operational research and deputy head of management services. Much of his time there was devoted to the development of the Bloodhound surface-to-air missile, which went on to become the UK’s main air defence weapon. “Bloodhound was a fascinating project,” he remembers. “We were starting from scratch, working out how to develop a homing missile: how to identify a target, how to make the missile go in the right direction and to be reliable. It was a huge learning curve.”

Eventually, Ayers left the company to take up a position in the family printing-machine firm.

“The job at the Bristol Aeroplane Company was becoming less secure. My father owned a printing firm, but his health was in decline. The firm employed a lot of loyal people, and it was clear that some big decisions were going to have to be made: we either keep it going or we shut it down. I wanted to give it a go for the sake of the staff. I ended up staying 20 years,” he says.

Eventually the firm was overtaken by technology, as photocopiers and then word processors came to the fore, forcing its sale.

Now Ayers is happily retired. Aside from his design role on the Bloodhound SSC land-speed project, he also enjoys spending time reading and playing bridge.