As the nights draw in and heating thermostats are turned up, boilers in lofts and kitchens throughout the country click into life. But in a growing number of homes, the familiar little flame in the boiler has been replaced by a coil of piping underneath the lawn. More people are installing ground source heat pumps to supply heat and, perhaps optimistically, hot water to their homes. More than 14,000 heat pump systems were sold and installed in 2009, double the number in 2008. Most experts say that the number will increase rapidly.

The sales pitch of cheaper heating bills, a reduction in carbon emissions, a government grant, and the prospect of the Renewable Heat Incentive (RHI) is encouraging take-up of air and ground source heat pumps. They have a proven track record in Scandinavia and Germany and are relatively straightforward in design. But are the systems installed in this country performing like they do in Sweden and Germany? If you install one will you save money on your bills and help save the environment – or waste thousands of pounds digging up your garden?

According to the latest study by the Energy Savings Trust (EST) on heat pumps, widely seen as the largest ever conducted, the respective answers are no and maybe.

The EST provides advice to consumers, government and industry on how to reduce energy usage, and has been conducting a field trial of 83 heat pump installations since November 2008, as well as surveying users. According to the initial results of the study, quite a few people have dug up their gardens for very little financial or environmental gain.

The EST found that only 13% of the 83 heat pump systems achieved a coefficient of performance (COP) and system efficiency of 3.0, the level of performance it deems as good, and which is normally achieved in other European countries by these devices. The bad performance has an impact on the environmental credentials of the systems.

All heat pumps require electricity to run and electricity has to be generated somewhere by some means, whether by renewable sources such as wind turbines, or fossil fuels like coal or gas. Using government figures for the amount of carbon produced by generating electricity today, the report finds that a heat pump produces 9% less CO2 than a gas boiler.

More worryingly for consumers, who have to lay out thousands of pounds on heat pumps, the economics also don’t stack up. With what the EST labels a “mid-range” system efficiency of between 2.3 and 2.5, a ground source heat pump would take 47 years to pay for itself using the savings made when switching from a gas boiler at current electricity prices.

The study blames several things for the poor performance. Primarily, the trials were conducted on some of the first heat pump sites in the UK, and many of the systems monitored had not been designed and installed correctly.

Efficiency and performance

There are two main measures of effectiveness to consider with heating – the coefficient of performance (COP), and the system efficiency.

The COP compares the amount of heat produced against the amount of electricity required to produce it. Although the heat source, ground or air, is “free” energy, all heat pumps require a small amount of electricity to run. Therefore the higher the COP, the more effective it is in operation. For example a heat pump with a COP of 3 means for every unit of electricity it takes, it gives back 3 units of heat energy.

The measure of system efficiency compares the amount of heat the pump produces to the requirements of the entire heating system, such as central heating and domestic hot water, as well as the electricity needed to run the pump. Similar to the COP, a system efficiency value of 3 means for every 1 unit of electricity used, 3 units of useful heat are produced.

Roger Nordman, of the Swedish SP Technical Institute, peer-reviewed the methodology for the trials, and explains: “The major difference is that the UK has particularly old and inefficient housing stock. The market is also more mature in the rest of Europe and installers have much more experience in installing the technology.”

Simon Green, head of business development for the EST, says: “The results are more varied than we expected, but a high-performing heat pumped installed today will save CO2 even when replacing gas condensing boilers due to the planned decarbonisation of the grid.

“We are securing extra funding to extend the trial to define the reasons for variation in performance so we can inform industry of good practice.”

The report recommends a “thorough review” of installation guidelines and training and says that the industry needs to devise norms and standards for the design and installation of systems. Mistakes occur during installation because several companies have to be used for the groundworks, to install the heat pump, to do the plumbing and electrics. The report also says that the controls for the system need to be simplified because in many cases users found them too complex to control the temperature of rooms.

Kelly Butler, marketing director for BEAMA, the British Electrotechnical and Allied Manufacturers Assocation, agrees that poor heat pump performance can be attributed to poor design and system commissioning. “For example, inappropriate sizing to the heat load or system requirements, and inadequate commissioning such as circulation pump settings,” he says. “However, the industry is addressing these issues through major investment in training and support. This year 2,000 installers have been trained. By 2020 around 8,000 will help install one million heat pumps.”

Most systems in the field trial were installed before the government launched its Microgeneration Certification Scheme (MCS), which aims to certify products and services in the domestic renewables sector to an established set of standards.

Among other things, the MCS requires installers to advise customers how to make their homes more energy-efficient when specifying heat pumps, things like insulation, and to specifically outline how much fuel will be saved once the system is installed. The scheme has certified 357 products and approved 370 installers. A further 200 installers are in the process of being approved.

Butler says: “We believe that government and industry investment will overcome some of the trial’s less positive results.”

This is not to say that heat pumps should be ignored. Around five million homes in the UK are not on the gas transmission network and get their heat from fuels such as electricity, heating oil or LPG. These homes offer both the biggest carbon and financial savings – a ground source heat pump uses 28% less carbon than an oil-fired boiler per unit of heat and will pay for itself faster.

According to David Mackay, chief scientific adviser to the Department of Energy and Climate Change, if all off-gas properties were installed with a heat pump it would save 10 million tonnes of CO2 per year and around £1.5 billion savings on fuel bills in a year. He says: “Heat pumps will be a crucial component of our low-carbon future, provided they perform well. It’s essential to conduct trials to establish best practice and perfect this technology for use in buildings throughout the UK.”

Is it worth installing a heat pump? The answer is yes, as long as they are designed and installed correctly, and especially if they are off the gas grid. The chances that they will get designed and installed quickly are improving as the industry matures.

But there is still a gamble to be taken. If energy prices increase, as predicted, and as long the Renewable Heat Incentive is introduced as promised by the government next April, the Energy Savings Trust estimates payback could shorten to around eight years. Otherwise it might be worth waiting for a fuel cell micro-combined heat and power boiler.

Ground source heat pumps

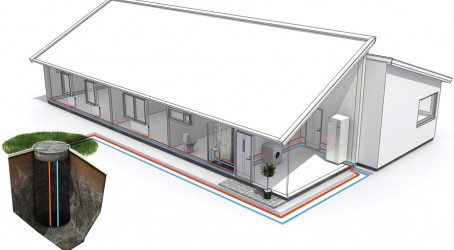

The easiest way to think of a heat pump is to think of it as a reversed refrigerator. Instead of removing heat from inside a fridge and dissipating it through the elements at the back, a heat pump removes the heat from the air or ground outside a house and puts it inside.

The process works by reducing the pressure of a working fluid so it evaporates at a very low temperature. This evaporation process needs heat, which is provided by the ground or the air. Then the vapour is compressed, raising its boiling point, so that it condenses into a liquid again.

In order to do this the working liquid needs to release the heat it has absorbed. The heat goes into the central heating system and domestic hot water store.

The most common type of ground source heat pump has a loop of high-density polyethylene tubing which is laid horizontally in a shallow trench, combined with a pressure-reducing valve and heat exchangers.

This is connected to a surface unit, which includes an electrically driven pump to circulate a mixture of water and glycol through the coil, extracting heat from the ground.

The longer the loop, the more energy the pump is capable of producing, so it is crucial that the size of the ground loops, whether horizontal or vertical, are matched to the peak heat demand and annual energy requirement of the property.

The ground loop can also be laid vertically in a borehole and work on the same principle as horizontal ground source heat pumps. The plastic tube is arranged in a U-shape going downwards into the ground.

Boreholes can be anywhere from 15 to 100 metres deep, depending on the heat demand from the house.

The ground maintains a fairly constant temperature under the frost line so unlike air source heat pumps, ground source performance does not fluctuate. However, installation of the ground loop can be expensive. Users have to have enough space to install it and the geology of the location has to be suitable.