Editor's Pick

Prospect Flow Solutions Ltd is an award-winning, multi-disciplinary engineering design and analysis consultancy services company providing to clients worldwide, and is a global division of the Hallin Group and Superior Energy Services Inc.

Operating within the international energy industries, Prospect deploys a wealth of engineering expertise and state-of-the-art technology to provide clients with a unique combination of technical services that deliver relevant, concise and usable engineering answers.

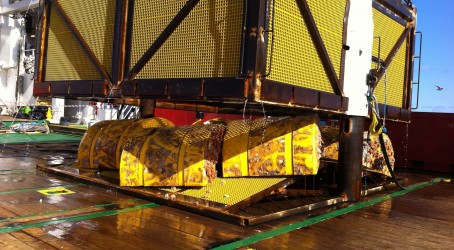

Prospect have recently carried out the successful detailed design of a unique Submerged Buoyancy Collector (SBC) for Swire Seabed AS. The project was a response to an unexpected emergency where around 131 buoyancy modules, weighing around 350kg each and having a combined buoyancy of over 40 tons were required to be removed from broken flexible risers.

The SBC was designed by Prospect to come in two parts: a base and a collection cage. The assembled SBC unit was deployed to the seabed where an ROV was manoeuvred to undo the locking pins allowing the collection cage to be raised off the base, leaving it behind. The cage was then transferred over the section of pipeline where the buoyancy modules were positioned and the module straps were then cut allowing them to float up into the cage above them. This procedure was repeated until the limit of the collector cage was reached and it was moved back to and reattached to the base, so that it could be lifted onto a vessel for unloading. Seabed AS repeated this process for all of the modules, until they were all removed from the pipeline.

Prospect utilised their multi-disciplinary engineering design and analysis capabilities to develop Seabed AS’s conceptual design to a working structure within their challenging deadline. AutoCad Inventor was primarily used to initially size and enhance the concept development. The structure was analysed and optimised using structural analysis software STAAD Pro, with complex regions validated using finite element analysis (FEA) in ABAQUS to verify the structural integrity of the area. Prospect provided the client with marine dynamic operational analysis of the SBC using the software application Orcaflex, which was used to check the stability and buoyancy of the SBC when fully laden and when empty.

Roger Tindley, Project Manager at Swire Seabed AS said “We had an idea of how to deal with the distributed buoyancy elements on the risers using ROV technology, but needed a detailed engineering analysis of its feasibility. A crucial aspect of the concept was the removal of the manual handling dangers inherent in a conventional recovery operation. Prospect carried the initial idea from design through to manufacture within a very tight schedule, by maintaining a close dialogue with ourselves and the constructors. We had complete confidence in operating the device within a few days of delivery, and it performed completely within specifications. This is the first time that an operation of this type has been performed, and will undoubtedly have an impact on future decommissioning projects.”

Ewan Giles, Prospect’s UK Sales & Marketing Manager, also added “Seabed AS are a fantastic client to work with who allowed us to get fully involved in a project rather than just be another subcontractor. The opportunity to undertake a larger, off the wall design project has allowed us to work closely together to develop a bespoke solution that fits the client’s requirements perfectly.”