With the announcement of the Google Lunar XPRIZE – a $20 million award to the first team to safely land a robot on the moon; travel 500 meters across its surface; and transmit images, video, and data back to Earth – the Carnegie Mellon University (CMU) professor founded Astrobotic Technology, Inc., and assembled a team to take robots into space.

As the Fredkin Research Professor at CMU’s Robotics Institute, director of CMU’s Field Robotics Center, and chief scientist of CMU’s Robotics Engineering Consortium, Whittaker has directed several innovations in robotics development, including the first robots to enter Three Mile Island after the nuclear accident, the NASA Nomad unmanned rover, and the computer-driven car that navigated city streets to win the 2007 DARPA (Defense Advanced Research Projects Agency) Urban Challenge. Now as CEO and CSO of Astrobotic, Whittaker leads a team striving to make space-based robots a sustainable business.

“In the past, Red would assemble a pickup CMU team in response to research challenges to show what is technically possible,” explains Steven Huber, COO. “With Astrobotic, we are building a company that will develop space-based robotic systems and technologies, as a revenue-generating business, in concert with our pursuit of the Google Lunar XPRIZE.”

Competing successfully against the 21 teams still in the running for the Lunar XPRIZE required an efficient design platform with robust visualization, communication, and manufacturing capabilities. Astrobotic chose SOLIDWORKS® Professional software because it met these requirements, integrates directly with MasterCAM® machining software, and is the primary CAD package used at CMU, from which the company’s staff has come.

“CMU is a SOLIDWORKS university, so we all have experience using the software,” Huber explains. “We view SOLIDWORKS as the CAD leader, and the ease of the SOLIDWORKS user interface is important to us. When tools are accessible, members of our staff can express their innate creativity more freely. From conceptual design to rendering to machining, we use SOLIDWORKS for everything we do.”

Designing robotic landers, rovers, and miners

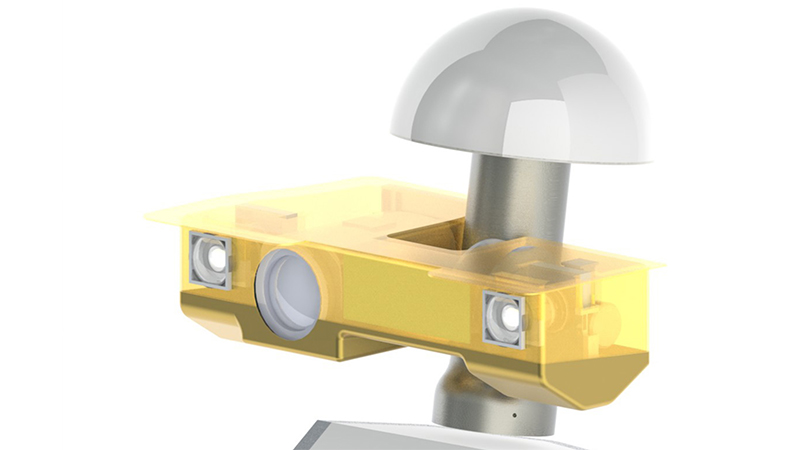

Using SOLIDWORKS, Astrobotic has quickly developed a landing spacecraft and solar-powered rovers for exploring the equatorial and polar regions of the moon. In addition to lengthening its lead toward winning the Lunar XPRIZE, the company is delivering affordable space robotics technology to meet the payload, exploration, and mining needs of other lunar and planetary missions, including several funded by more than a dozen NASA contracts.

“The SOLIDWORKS platform enables us to deliver on time at an affordable price,” Huber stresses. “Every team member relies on SOLIDWORKS to design and communicate. For example, whenever we come up with a new design, we create renderings to drive annotated slide shows to facilitate design reviews. We make extensive use of the RealView feature for this purpose.”

Riding the Falcon 9 rocket

Astrobotic’s innovative navigation and landing control technologies attracted the attention of Space Exploration Technologies Corp. (SpaceX), which made history as the world’s first privately held company to send a cargo payload to the International Space Station, when its Dragon spacecraft docked with the orbiting outpost in May 2012. The two companies have signed a contract to carry Astrobotic’s lander and robotic payload to the moon on the SpaceX Falcon 9 rocket in October 2015.

“We are passionate about reaching the moon, establishing a sustained lunar presence, and ushering in the space-based robotics industry,” Huber says. “With SOLIDWORKS, we are developing a new generation of space hardware and robotic systems that utilize our highly accurate navigation and trajectory-control technologies, which enable us to land robots within 100 meters of any point on the moon.”

Taking advantage of emerging opportunities

In addition to leading the race for the Lunar XPRIZE, Astrobotic has won NASA contracts to develop robots to mine the moon for water and methane, explore lunar and Martian caves, and land on asteroids, as well as build a low-gravity facility and study how robots can prepare a permanent NASA lunar base. The company has also cultivated a growing payload delivery business for carrying scientific and commercial payloads to the moon.

Astrobotic Technology has leveraged SOLIDWORKS Professional software to develop its lunar lander and execute NASA contracts to develop robots to mine the Moon for water and methane

“At Astrobotic, we’re establishing a growing company that’s involved in every aspect of using robots in space,” Huber explains. “Using SOLIDWORKS, we are well on our way to creating robots that help mankind travel back to the moon and beyond.”

Robotics pioneer and Carnegie Mellon University (CMU) Professor William L. “Red” Whittaker founded Astrobotic Technology, Inc., to win the $20 million Google Lunar XPRIZE and launch a robotics industry in space. In addition to trying to become the first team to safely land a robot on the moon; travel 500 meters across its surface; and transmit images, video, and data back to Earth, Astrobotic is committed to making space-based robots a sustainable business. To achieve these goals, the company needed an efficient design platform with robust visualization, communication, and manufacturing capabilities.

Astrobotic chose SOLIDWORKS® Professional software because it met these requirements, integrates directly with MasterCAM® machining software, and is the primary CAD package used at CMU, from which all of the company’s staff has come. Using SOLIDWORKS, Astrobotic has established itself as the leading Google Lunar XPRIZE team, developed systems for its October 2015 lunar launch, attracted additional robotics contracts, and developed robots for other space-related uses.

Challenge:

Efficiently and cost-effectively develop robotic systems to meet space exploration and landing demands, vie for the Google Lunar XPRIZE, and take advantage of space-based economic opportunities.

Solution:

Utilize SOLIDWORKS Professional design software to drive research and development.

Results:

- Established itself as leading Google Lunar XPRIZE team

- Developed systems for its October 2015 lunar launch

- Attracted additional robotics contracts

- Developed robots for other space-related uses

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.