Shaping up: Motion capture technology is used to track virtual-reality headsets in digital prototyping

Gesture control and motion tracking are coming of age. This year Volkswagen will launch its first car that will recognise hand movements to control the infotainment and air conditioning.

Want to control your computer through the electrical impulses in your arm muscles? The Canadian-developed Myo device does that and will be available later this year. How about tracking your run or the number of steps you take each day? Take your pick from a number of wristbands and apps.

There are two main ways of tracking human motion and position – optically and through the use of sensors such as accelerometers. Gesture controls have been applied in computing and video games for several years, notably in devices such as Microsoft’s Kinetic and Nintendo’s Wii. The technology’s latest integration into cars and consumer devices is driven principally by the sensors and cameras getting better and cheaper.

Swiping and pointing in the air instead of pressing buttons to control a device may not impress or even appeal. But the improvements to cameras and sensors and the software behind them mean that motion tracking is also being used more by engineers – from improving the ergonomics of products to increasing productivity in factories.

An indication of the progress that has been made comes from Dutch company Xsens. Last month it launched a wearable inertial sensor system that at £15,000 for the hardware and one year’s software licence is around half the cost of its predecessor. The Awinda system is also smaller and more accurate than its predecessor, opening up more applications in studying machinery motion and improving ergonomics in product development, says the company. It tracks the movement of its wearer using Mems sensors worn at points around the body.

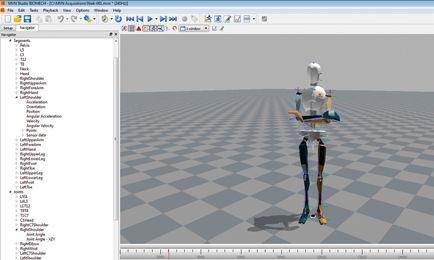

The hardware fits into a backpack and connects to a computer. It takes minutes to set up as the subject wraps up to 17 sensors around their wrists, head, waist and shoes. The wearer has to stand still for several seconds while the sensors calibrate. The Xsens software then fuses the data from the sensors with biomechanical models to produce a 3D output on the computer screen. The wearer has freedom of movement within the receiver’s range, and can wear the system outside, for example to track sports activities. The data can be integrated into software packages, such as Catia for design and Siemens Jack for manufacturing planning.

Xsens’ inertial sensor technology was spun out of research done at Twente University in the Netherlands 20 years ago. The system has been used for biomechanics in academic research and sports training as well as in the entertainment industry for years. But the technology is just as applicable for use with industrial machinery, says Xsens product manager, Colleen Monaghan. She describes the system as “a tool that puts real human movement into a 3D simulation”.

“In 2006 the automotive industry made the sensors we used. Now they come from mobile phones,” she says. “The growth and development of the components, the reduced power requirements and size makes them simpler and more stable to use. The sensors are now wearable and more affordable.”

Wearing well: Xsens system fuses data from sensors with a 3D body model

Wearing well: Xsens system fuses data from sensors with a 3D body model The technology is being used by engineers in product development and to optimise production lines, checking posture and simulating worker motion within virtual designs. Such applications have grown significantly since integration with the 3D software packages.

Xsens’ biggest business sector is now what it calls machine motion. Monaghan says: “A lot of companies have the software packages already. Once you stream the data into them, word has spread about the tangible results. It’s a growing trend.”

The main competition for sensor-based tracking systems is optical-based systems. Oxfordshire-based Vicon is one of the leading suppliers of optical-based motion capture systems. The company, which was founded in 1996 and is part of the Oxford Metrics Group, also has its roots in providing motion tracking for the life sciences and the entertainment industries. However, during the last several years the company has seen the amount of engineering customers grow to account for just under a third of its business.

Warren Lester, engineering product manager at Vicon, says: “There is a strong trend for motion capture in engineering. Engineers are becoming more aware of the technology. Optical tracking has been around for a long time, but the technology is getting cheaper and more accessible.”

Unlike sensor-based motion capture, optical systems work by taking a series of images from cameras positioned in a fixed installation in a workshop or laboratory. The cameras measure the position of reflective markers worn by the subject. The software translates this positional data into a usable form on the computer and can output it to other software, such as Siemens Jack and Dassault’s 3D packages.

The number of cameras and markers differs for each application, but in design processes as few as four or five markers and two cameras can be used to track and measure movement. An automotive firm, for example, could use a Vicon system to assess the ergonomics of a driver getting in and out of a car. The largest installation the company has ever worked on for an engineering firm is a 140-camera system for tracking robots in a large industrial space.

Optical systems such as Vicon’s are also an integral part of virtual prototyping. Companies such as Ford in Detroit and the Atomic Weapons Establishment in Aldermaston are using virtual-reality headsets to enable engineers to explore the interiors and exteriors of prototypes.

Once installed, virtual reality negates the need for models and significantly reduces the costs of design and development phases of projects. Lester says: “We generate a precise position of the head-mounted display the user is wearing, so that the 3D software can render the image in the display the correct way.”

Apart from mechanical design and ergonomics, one of the latest uses of the technology is in the design of control systems for unmanned ground and aerial vehicles. The technology can be used to track how a vehicle moves over different terrain, or to pinpoint the position of an unmanned aerial vehicle (UAV) in the sky, says Lester. As more UAVs are used in civilian airspace and strict certification requirements have to be met, data on the responsiveness of controls and their aerodynamic behaviour is increasingly useful.

There are benefits and disadvantages to the use of either optical- or sensor-based motion tracking because they work in different ways. In optical systems cameras need to see the markers, and if occlusion occurs tracking can be lost. Installations are fixed, so motion cannot be tracked outside the lab or workshop and costs may be higher. However, they offer millimetre-precise measurement, based on positional data.

Lester says: “Sensor-based systems are good and can be put on and removed quickly. But they are not as precise as an optical system.”

But Monaghan says Xsens’ inertial sensor-based motion tracking now rivals the accuracy of positional data. “We measure orientation, and the measurement is perfect,” she says. “People are used to millimetres and if you have access to a laboratory you can rely on an optical system. But for things like measuring joint angles, there is no need for positional data.”

It’s likely that the appropriate technology for your application will depend on a number of factors: inside or outside, time and cost, the precision required. In some cases the different technologies can be seen as complementary in the design process.

Motion tracking though is undoubtedly becoming cheaper and easier to use. As it becomes more commonplace in engineering development and consumer devices, innovative uses for it will become more prevalent.

Work flow: Motion capture data is integrated into 3D planning software to improve factory layouts