Engineering news

Designed by engineers from Purdue University in Indiana, the Flow Boiling and Condensation Experiment (FBCE) aims to improve understanding of heat transfer in microgravity.

The experiment, which reached the ISS last Thursday (12 August), addresses two key issues for spacecraft engineers – reducing weight and managing extreme temperatures.

“Vehicles like the space shuttle used single-phase cooling, which circulates liquid through tubes to remove heat from the avionics,” said principal investigator Issam Mudawar. “But these systems are complex and add a lot of weight to the spacecraft. What we’ve been exploring is using two-phase flow, which is more efficient and reduces the size of the cooling hardware.”

Two-phase flow refers to the two phases of matter – liquid and vapour – that happen during boiling and condensation. In a process known as flow boiling, a specialised liquid flows by a heat source, which causes the liquid to boil and create bubbles. Those bubbles of vapour flow past the heat source, reject the heat, and then condense back into liquid, which recirculates constantly in a closed system.

The process is highly efficient and well-studied, but its efficiency in space has remained unknown until now.

Previous experiments on parabolic ‘vomit comet’ aeroplane flights provided positive results, Mudawar said. “We discovered that at certain flow rates, microgravity actually did reduce the amount of heat flux by up to 50%.”

Mudawar and colleagues at the Glenn Research Centre developed a smaller version of the experiment to fit in a specific rack on the International Space Station, and it passed NASA’s safety and readiness reviews in March.

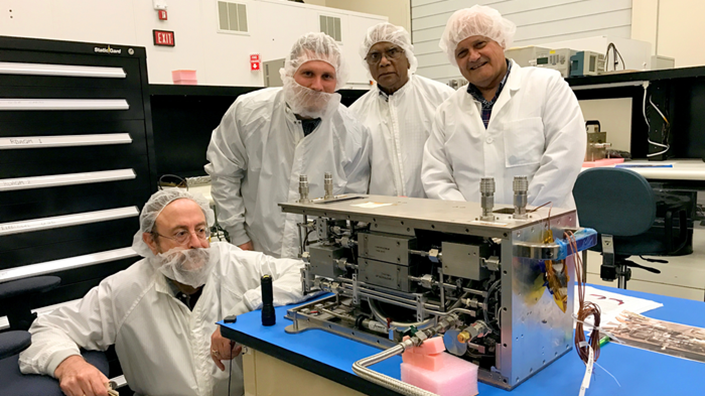

Issam Mudawar (left) inspects one of the modules of the Flow Boiling and Condensation Experiment (Credit: Purdue University)

“This is no small task,” Mudawar said. “Every single structural member needs to be optimised for weight and size. Every single screw has to be evaluated and certified. It’s actually good preparation for trying to make future spacecraft lighter, which is what we’re trying to accomplish.”

Astronauts will soon run the science equipment through operational readiness reviews and, later this year, will begin to conduct the experiment.

“This is truly a milestone for Purdue’s space research,” Mudawar said. “This will be the largest phase change experiment ever conducted in space. Hopefully, what we learn from this experiment can be used to make future spacecraft more efficient, and enable us to go to the moon, Mars and beyond.”

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.