But for metrology coordinator Beatrice Alix and the rest of team assembling the world’s largest nuclear fusion demonstrator, it is the small numbers that count. The 100 micron (µm) alignment for interfacing between conductors, for example, or the maximum uncertainty of 0.25mm for the position of components that weigh dozens of tonnes.

Precision is key and the stakes could not be higher. The goal at Iter (which stands for International Thermonuclear Experimental Reactor) is, in the words of chief scientist Alain Becoulet, “creating a Sun here on planet Earth”. If the team succeeds, they could transform global electricity production – but if they fail, it might scupper hopes for our most promising future power source.

First, however, they need to finish building it. Metrology contractor Hexagon invited a group of journalists for a behind-the-scenes tour of the facility in the south of France as the team prepared to add the second of nine key modules to the reactor.

A human adventure

Thick forest leads up to the barbed-wire fence of the 180-hectare Iter (pronounced ‘ee-tear’) site, which juts out from the rolling landscape. The rugged brown hills of Saint-Paul-lès-Durance, overlooked by the snow-capped Alps in the distance, are covered in scraggly woods of olive, pine and cedar. In early May, the famous Provence lavender is not yet in full bloom.

Entering the security checkpoint, the first thing you notice is the row of flags: China, the EU, India, Japan, South Korea, Russia and the US standing proudly next to each other. This is a collaboration that transcends national disputes in search of practically limitless clean energy.

The international project is a “human adventure”, says communication officer Sabina Griffith. Sitting in the board room (which, with its long oval table, is more than a little reminiscent of the war room in the film Dr Strangelove), she sets out the project’s vision.

“The Sun and the stars, these are our role models. And for decades, centuries, mankind has thought about ways to make this vast energy accessible for us here,” she says. “Down here on Earth, we have to play a lot of tricks.”

Those tricks will take place in the doughnut-shaped tokamak reactor, the largest ever built. The fuel, hydrogen isotopes of deuterium and tritium, will be heated to incredible temperatures inside the reactor, creating a spinning cloud of plasma. That will be contained and compressed by immensely powerful magnets, forcing the positively charged atoms together. When they collide, they will fuse to form heavier helium nuclei, releasing neutrons with vast amounts of energy. Those will hit the steel walls of the reactor, transferring kinetic energy into heat.

Iter will not be the first project to make that happen. Dozens of fusion reactors have been built – West, the world’s first superconducting tokamak, is just next door – and many more are planned. Iter’s distinguishing feature is its incredible size, with a plasma volume five times bigger than previous reactors.

The project's board room

Think of a nightclub, Griffith suggests. There are fewer people on the dancefloor at the start of the night, with slower music. More dancers join in as the DJ increases the tempo and turns up the volume, increasing the chance of collisions. Iter’s enormous scale allows the DJ to blast the tunes as loud as possible.

That approach should allow Iter to clear major hurdles, the developers hope. The fusion conditions should be sustained mostly by heat from the fusion reaction, which in turn should release more energy than is put in. Engineers are aiming for a fusion energy gain factor (Q) of 10, meaning it should turn the 50MW of input heating power into 500MW of fusion power. That output will produce hot air and steam, with electricity generation not part of the project. In future power plants, the steam would drive turbines to generate electricity.

Those future projects are the reason for Iter, which has been described as the most complicated engineering project in human history.

“This is really a key experimental step between today’s fusion research machines and tomorrow’s fusion power plant,” Alix says. “We are in a very tricky [position] here, trying to achieve this big challenge of building Iter as well as possible.”

Things great and small

Standing outside the assembly hall after a short shuttle from the board room, it is difficult to grasp its true scale. The telltale signs of ascending storeys are absent, the shiny corrugated walls instead punctuated by single vents, pipes or protruding staircases. There is one revealing measure, however – look towards the roof for a few seconds and your neck will start to hurt.

Walking inside, the scale is still hard to judge. Workers with red and white helmets scuttle around giant scaffolds in the cavernous workshop, where components are cleaned and placed in bespoke lifting tools to be moved and assembled. Here, the nine modules of the doughnut-shaped vacuum vessel are put together on huge ‘sub-assembly’ structures.

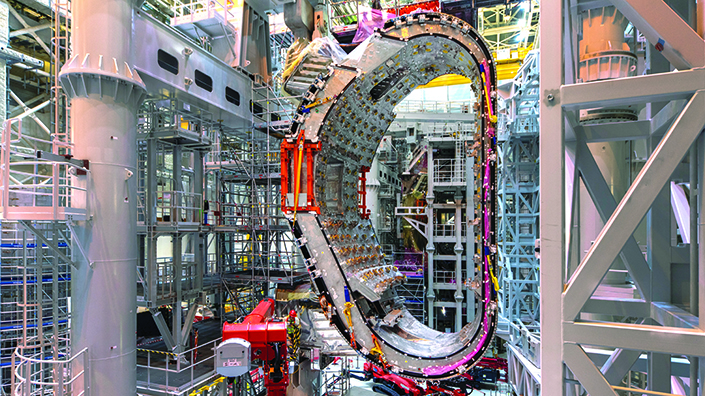

One of the nine D-shaped modules

Five storeys tall and weighing as much as four fully loaded jumbo jets, the D-shaped modules consist of a core sector structure, thermal panels for insulation and a pair of toroidal field coils, which will confine the plasma particles during operation. In early May, one has recently been placed in the adjacent tokamak pit, while another is being carefully assembled. The central solenoid magnet stands nearby, a tower wrapped in scaffolding, with four of six modules already stacked on top of each other. When complete, its magnetic field will be so strong it could levitate an aircraft carrier.

Watching the diligent and methodical work going on around the hall, it is easy to forget that the giant components are the first of their kind. Great care is needed to prevent potential issues such as collisions between the vastly expensive parts.

Measure for measure

When complete, the reactor will be a bit like a “nuclear Swiss watch”, according to Becoulet. “We need the precision of a Swiss watch but with the size of nuclear activity. So it’s a bit of a paradoxical challenge.”

Tackling that challenge requires a forensic focus on metrology, the science of measurement. At Iter, equipment from Swedish multinational Hexagon includes probing systems and scanning devices for large volumes, as well as handheld scanners for close-up assessments.

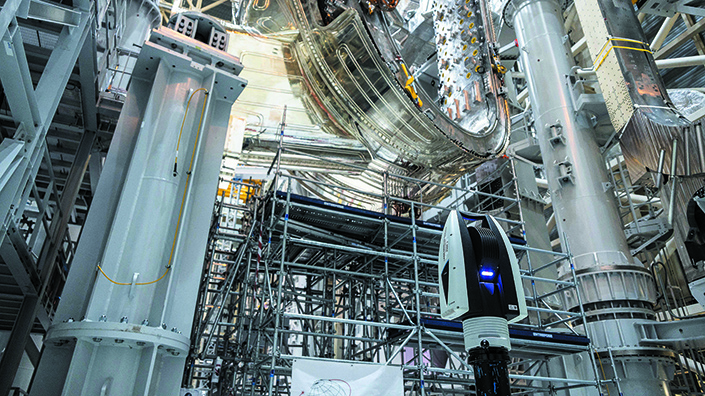

The half-assembled vacuum vessel module, currently being worked on by crew members in a cherry picker platform, is covered in small red plates and reflectors, creating an invisible web of hundreds of lines of sight. These enable high-speed dynamic measurements from the Leica Absolute Tracker AT960, which probes, scans and inspects with six degrees of freedom to ensure everything is where it needs to be.

Hexagon's Leica Absolute Tracker ATS 960

The system uses the Absolute Scanner AS1 for non-contact 3D measurement. A modular design means the scanner can also be used on portable measuring arms without realignment, a useful time-saver in such a high-intensity assembly.

The metrology team will also be responsible for risk during the operation and maintenance of the reactor, both of which will create their own hurdles, Alix says.

Components sitting at room temperature will face not only extreme heat but also temperatures of -269ºC from the liquid helium needed to achieve superconductivity in the reactor’s magnets. Those extremes will cause components to deform and change shape, so precise clearances between parts must be set and maintained around the machine.

Fiducial nests

Once modules are ready for assembly, a short crane ride awaits. In a process that can take 36 hours, a ceiling-mounted crane lifts the 1,350-tonne parts up, across the assembly hall wall and above the adjacent tokamak pit. They are then gently lowered into the pit, with work pausing whenever instruments show any swing from the pendulum effect. “There are metrology cameras everywhere,” says Griffith. “Once it’s lowered, it will remain in its almost final position for two or three days, until the metrology team say ‘Go’. It has to be aligned with sub-millimetre precision.”

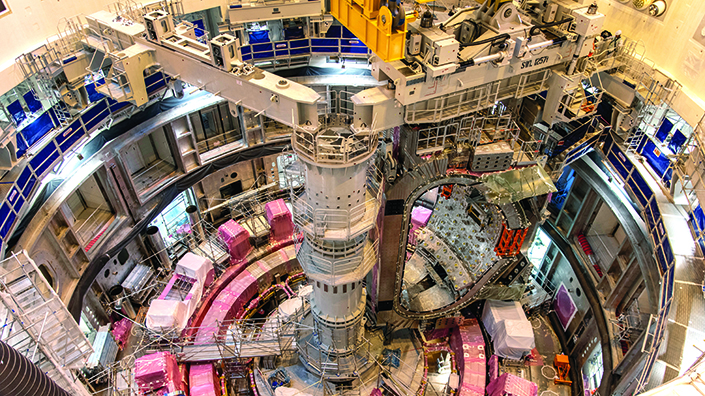

Standing on a platform looking down into the pit, the tokamak feels like the inside of a space station. Workers busily move around different sections of the 28m wide, 29m tall reactor, which will include more than 1 million parts. Every piece must seamlessly integrate into the whole, regardless of its origin in the supply chain in any of Iter’s 45 member states.

Looking down into the tokamak pit

Red laser reflectors and yellow targets known as ‘fiducial nests’ on surfaces around the giant volume allow the metrology team to reference each component in space while everything is visible and accessible. Key fiducials, which will still be visible after assembly, will provide reference for the final shape of the machine.

Each of the nine sector modules should be in place in 2027. After that, two and a half years of welding will begin, completing the vacuum vessel. A combination of manual and robotic techniques will be used on 40km of passes, with internal metrology tracking any structural changes. Some welding shrinkage is expected so deep scanning will check for affected areas.

Metrology is key for predicting and countering any potential future issues, Alix explains. “None of these components are perfect. Obviously nothing is built exactly to design, and that’s why we need to have the as-built shape,” she says. “Anything that is below 50mm [clearance] is a warning area for us; there should be spotters to look at those locations. And anything below 10mm clearance is considered as a clash, and mitigation has to be implemented in that case.”

SpatialAnalyzer software from Hexagon enables the Iter team to validate the constructed machine against the original design. Reverse engineering goes hand-in-hand with metrology, with any deformations digitally replicated to highlight areas that might need future attention.

“We require real measurement of as-built components, then do a ‘virtual fitting’ to compare with the CAD files in the hybrid model. This data is then combined with the supplier data,” Alix says. “This set of data helps us to identify any deviations, repairs, clashes, collision rates or potentially not being able to assemble as designed. It saves both cost and time, so it is key to the success of the project.”

Digitalisation of the reactor will also be key for its eventual operation, which should start from 2034.

“The moment we switch on the machine, it should work,” Becoulet stresses. “We are very significantly augmenting our capacity to manage all the knowledge, all the data, all the information we have of all these subsystems… we are embarking on a very ambitious digitalisation of all the facility, the systems and so on, in order to perform efficient operation.”

‘Fusion is our sport’

None of this comes cheap. The project is expected to cost more than €25bn, up from original estimates of €5bn. It is also far from easy and the work has been dogged by repeated delays, with energy-producing reactions not expected until 2039.

If the project is successful, however, it will benefit countries around the world. The international collaboration is remarkable in the midst of external conflict – but, as the Iter team points out, collaboration on tokamak reactors has been ongoing since the frigid depths of the Cold War, when a delegation of British scientists from the Culham Centre for Fusion Energy visited and validated a Soviet machine in the 1960s.

The Iter project itself was kicked off in earnest by a fireside conversation between US president Ronald Reagan and Soviet Union president Mikhail Gorbachev in 1985, long before the international consortium came together to sign a formal agreement for its construction in 2006.

“With the war going on in Ukraine, we had many discussions in-house and on political levels [of] what to do with our Russian partner,” says Griffith. “The answer is very easy. Russia is and remains a partner of Iter because our goal is to deliver fusion energy. We try to stay out of geopolitical tactics and so on. This is not our turf. It’s a bit like the Olympic Games, you know? We try to focus on the sports, and fusion is our sport.

“It still gives me the goosebumps, sitting in these meetings. To observe these nations that are outside at war with each other, or have been at war with each other not so long ago. The US, Japan and Europe, and so on. And here we are discussing – openly discussing – a new nuclear technology, a peaceful use of nuclear technology.”

Members of the international project inside the reactor's poloidal field coil

The work at Iter is “apolitical”, Becoulet says. “We don’t need to deal with this. The flags are the flags of our members. If they want to fight against each other, it’s their point, not ours.

“So we refrain from doing any politics inside – which, by the way, I think is the right thing to do. If you don’t like China or the US today, you just quit the project yourself.”

He adds: “We are proud of being an example… we think that science is one of the areas where this diplomacy is extremely important, and maybe very fruitful.”

The UK is one country that will not automatically share that bounty. It left Euratom (the European Atomic Energy Community) and Iter following Brexit, and both the UK and EU have reportedly snubbed approaches from each other for renewed involvement in the programme. The two are “moving closer”, however, Griffith says in May.

With the Trump administration cutting billions of dollars of science and research funding, there are also fears the US could pull out – but with much of the investment already made, it would likely be the biggest loser from such a move.

The first of many?

Despite the grand scale, the giant price tag and the international significance, Iter is a prototype. But if it can prove the technology works and show how it can provide huge amounts of energy with relatively small amounts of fuel, its developers hope it will be swiftly replicated at utility scale around the world, transforming the fight against climate change in the second half of the century.

The aim is to establish a fusion industry around the world, Griffith says: “Once we have Iter and Iter says, ‘OK, go’, we can do it. This industry is ready to kick in, we multiply what is learned, we have people that are trained on the job, we don’t have to start all over, again and again. Here is where the private sector and other new projects are essential, to keep this industry and the knowledge containment alive.”

A giant component is transported by road

Speaking to employees of Iter and Hexagon, they clearly share an emotional connection to the transcendent possibilities of the project. Contract manager Méhand Idri, who previously worked for the measurement-focused company but now works for Iter, says he is even delaying his retirement by a year because he feels this project is so important for future generations.

There is a long way to go and it remains to be seen if Iter will be successful in its objectives – but, at the moment, it feels like things are moving in the right direction. 2024 was the first year the project delivered on schedule and to budget, and the assembly team aims to accelerate its work over the next two years.

Metrology is a key part of ensuring that Iter can be replicated. “Iter is a one-of-a-kind project,” says Wandrille Vallet, vice-president for new industries at Hexagon Manufacturing Intelligence. “But after that, when you go through to other industries, you need to do it at scale. You need to be able to repeat that.” Ultimately, those tiny measurements and tolerances could end up having a giant impact.

A recent report on the importance of metrology in the engineering industry, entitled The Power of Precision: How Better Measurement Drives Engineering Excellence, was published jointly by IMechE and the National Physical Laboratory. Download the report here.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.