You’re feeling fit and mobile, but notice that your strength isn’t what it used to be and you’re struggling to lift a cup of tea to your mouth. So off you go to the clinic where the doctor makes a tiny incision in your arm and slides in an artificial muscle to supplement your ailing muscle. Your strength is restored and tea drinking is no longer an issue.

It sounds like science fiction, but in 30 years this could be our reality. “It seems a radical jump, but this is our goal and we know how to get to it,” says Jonathan Rossiter, professor of robotics at the University of Bristol.

Rossiter is leading the emPower artificial muscles research project. Deploying engineered robotic artificial muscular assistance inside the body, the aim of the project is to overcome the limitations of current wearable assistive technologies and regenerative medicine to help cope with muscle ageing and disabilities.

The human body has more than 600 muscles, which make up 40% of our weight. These muscles help us move, enable us to interact with objects and the environment and regulate critical internal functions. However, they are susceptible to damage as a result of trauma and various health conditions including sarcopenia (age-related loss of muscle mass and function), stroke, muscular dystrophy, multiple sclerosis, soft-tissue cancers, venous ulceration, diabetes, degenerative myopathy and incontinence.

“There’s a whole suite of people that we are looking to help with our project. We are working on the principle that implanting robotic, artificial muscles to replace or work alongside our own muscles can restore natural body function and help us all to live longer, more comfortable and active lives,” says Rossiter. “Almost anywhere where you have a muscle you could replace it with an artificial muscle. That’s the goal.”

The emPower project is being funded by the Engineering and Physical Sciences Research Council (EPSRC) through its Transformative Healthcare Technologies for 2050 programme. This programme will support the development of technological approaches to transform care and treatments in the NHS by 2050.

Having kicked off in March 2021, the emPower project is just at the starting blocks and is bringing a range of leading experts together in its race towards a successful outcome. This multidisciplinary team consists of 30 researchers across soft robotics, materials science, bioengineering, chemistry, ethics, healthcare regulation and medicine.

Rossiter says: “Crucial to this project is having top clinicians working together with engineers and bioscientists as well as key industrial and social-care partners. Utilising this pool of expertise, our vision over the next five years is to deliver the foundational technologies and first-stage proof-of-concept of the emPower artificial muscles.”

How it all started

As professor of robotics, Rossiter is also head of the soft robotics group at Bristol Robotics Laboratory. Soft robotics is an area of research and development that he has been working on for the past 15 to 20 years. Unlike conventional rigid robotics, soft robotics are made of pliable materials that can stretch, bend, twist and move without the need for traditional motors. They’re more akin to a biological organism and their softness makes them far more suited for interaction with the human body.

Rossiter and his team have developed a range of autonomous soft-robotic devices that merge with humans in some way. For example, the Right Trousers project, an EPSRC-funded initiative now known as the Freehab project, is a wearable power trouser made from supportive soft-robotic material. These artificial muscles inside the clothing work with the body’s own muscles and aim to give older people and those with disabilities the control and power to move around.

Rossiter says: “This is a good solution for the next 10 to 20 years but it’s not a long-term solution. Although these wearable technologies and other such exoskeletons help the muscles to move, they do so by pushing against and potentially damaging the skin. They are treating the symptoms, rather than the underlying cause, of weakness. Instead, we need to look at muscles and how they work deep inside the body.

“This led to a natural transition into the emPower project where we are able to take artificial muscles and slide them under the skin where the original muscle connects with bone. Once the muscle is powered up it will lead to movement inside the body, skeleton to skeleton, bone to bone, exactly where it’s needed.”

Exploring the physics

So what will these emPower muscles look like? That is the big question that Rossiter and his team will be researching over the next five years. “We know we can do it but what’s the best way to do it?” he asks.

The initial step is to explore all the possible physics that could lead to muscle-type activation. In other words, generating a prototype muscle whereby a stimulus is applied that causes it to contract. However, the challenge here is taking what is essentially micron- and nano-level actuation movement and turning it into something that is big enough to be put into the body.

A credit card-sized electro-pneumatic pump for use in soft robotics

“Nature does it really well,” says Rossiter. “Using a molecular ratchet mechanism, when the muscle is stimulated one molecule bends to grab onto another one, pulls it, bends again, grabs onto another one, and so on. This happens at a scale of about 2 nanometres and is then scaled up by biology into the centimetre scale of bulk muscle action.

“As we explore the physics we need to take these hierarchical structures into account – that something that fundamentally works at the nanoscale, scales to the micron scale, scales to the millimetre scale, scales to the centimetre scale. Each one of those could involve a slightly different technology or a slightly different structure.”

Manufacturing skills

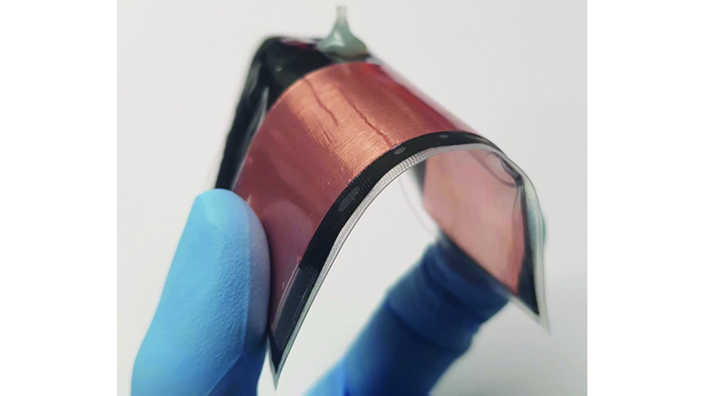

The team has already done groundwork in this area through R&D into various robotic actuator projects, including electro-origami, electro-ribbon actuators that are able to contract by 99.8% of their length and deliver specific energy and specific power equivalent to muscle.

It’s also an area where bringing in the various project partners will be useful. Rossiter says: “For instance, Renishaw is very good at making delicate and complex structures with their manufacturing methods. So we have the potential to work with their skills to make structures which will bridge the scales from the very small to the very big, and that’s very exciting.”

However, there is a wide range of materials that these muscles could be made from, even biodegradable materials. For example, the aim for the emPower muscles is for them to be used in both short-term rehabilitation as well as long-term assistance, and in the former it may be that, once the patient has recovered and their muscle strength is restored, the emPower muscles then degrade safely within the body.

While the physics are being explored, a key consideration is that the emPower muscles must be biocompatible and work seamlessly with the body. For this reason, as the project advances, its multidisciplinary team will explore how neural signals from the nervous system and the brain enable muscle control. The aim is to develop an artificial motor neuron, which will enable bidirectional control by taking information from the brain and turning it into muscle activation.

Then there is also the issue of ethics. The aim of the EPSRC’s Transformative Healthcare Technologies for 2050 programme is to fund projects that develop approaches that could become routine in the NHS and home care in the coming decades. With any breakthrough technology there is always potential for an ethical roadblock.

“We have a full-time ethics team and right at the beginning we are doing a study on the ethics and the social acceptability of these artificial muscles. This team will be talking to leading experts as well as the public, understanding what they want and taking into consideration everyone’s opinions,” says Rossiter.

One of the key questions this project will raise is on the use of emPower muscles to strengthen people beyond the limits of normal muscles. The potential is that they could turn themselves into a superhuman or, as Rossiter puts it, a soft robotic human cyborg.

Tough questions

“With the project we want to help people who’ve got muscle weakness by restoring them to their previous level and enabling them to move around and be independent. This in turn will have major healthcare, economic and social impacts.

“But it also then raises the question of artificial muscles being used by people who are generally healthy but want extra strength, say if they have a very physical job. This is a very interesting question about the augmentation of humans. We are going to have to address this as a society, and projects like emPower help by directly asking these tough questions,” says Rossiter.

To reach that stage, however, there is considerable work to be done, which Rossiter is relishing, and he is fully confident that we can expect to see emPower artificial muscles in clinical use before 2050. “The project is certainly complex and challenging, but it’s fun. And, although we don’t currently have all the answers, we do know how to find them,” he enthuses.

Get to grips with the future factory: sign up now for our Advanced Manufacturing briefings (19-23 July), part of the Engineering Futures series.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.