It is a sentiment shared by John Egan, North West regional lead at Progressive Energy, who is keen to see action in getting CO2 emissions removed out of the economy – sooner rather than later: “What matters is actually getting on and doing it quickly and at scale rather than spending time doing it perfectly,” he says.

“The 30-year gap until we reach net zero in 2050 can desensitise us to the ticking clock. While technologies might be under development to address CO2 emissions to meet this deadline, in the meantime more CO2 is being released into the atmosphere. So, making big reductions quickly is more important than perfection later on.”

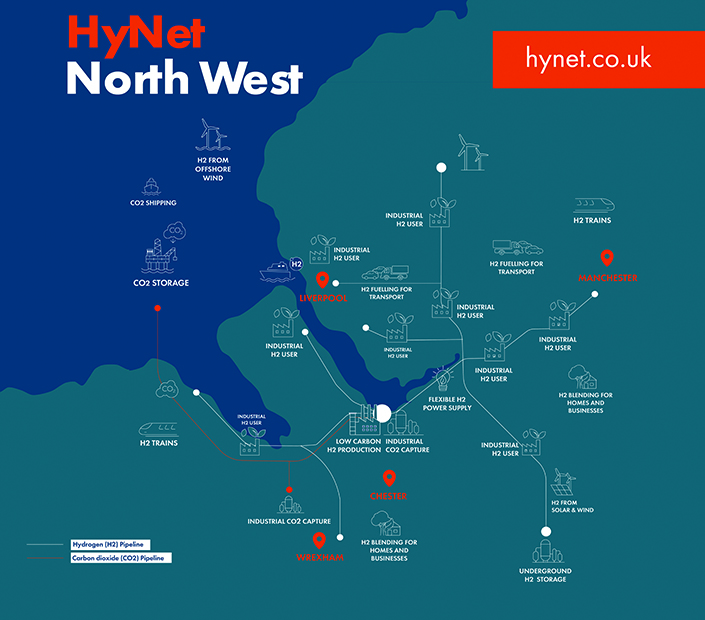

HyNet North West is the initiative that Progressive Energy, a project development company, has created to get on and do this. From 2025, this ambitious and large-scale project aims to produce, store and distribute hydrogen as well as capture and store carbon dioxide from industry in the North West of England and North Wales.

For this to happen, Progressive has brought together a consortium of eight core partners, including Cadent, Essar, Inovyn, Eni, the University of Chester, CF Fertilisers and Hanson, which are developing the main infrastructure for the project. In the first phase, Progressive Energy is leading the consenting of the CO2 pipeline, which will enable carbon capture and storage (CCS), as well as forming a joint venture with Essar to build and operate the first two low-carbon hydrogen production plants.

“Progressive Energy created the idea for HyNet several years ago and have since brought together the right partners to deliver it,” explains Egan. “In the first instance, we will produce hydrogen at scale at the low-carbon plants that will enable industry in the North West to switch away from fossil fuels to clean-burning hydrogen. We’ll also be transporting CO2, which has been captured from this plant as well as from industry in the area, to the depleted gas fields in Liverpool Bay for permanent storage.”

Hydrogen economy

The hydrogen economy has been promised for many years because, as with electricity, it doesn’t emit any CO2 at the point of use. But, while huge strides have been made in recent years to decarbonise electricity generation through renewable energy sources, according to Progressive Energy, electricity only makes up 20% of the energy we use, with the UK gas networks transporting roughly three times as much energy as the electricity network. Switching to renewable electricity is not a solution for everything as there are sectors of the economy that realistically cannot currently be electrified, particularly energy-intensive industries.

However, as Egan says, it’s these industries that are calling out for change. Many want to decarbonise and produce low-carbon products but the question is how do they do it? The answer lies in a project such as HyNet. “While the desire for change is there, we can’t expect each site on its own to solve this huge problem of decarbonisation. We need shared infrastructure, expertise and systems so that we can work collectively to solve it and solve it at scale,” he says.

This is why, as well as the eight core partners, a large number of supporting organisations have joined the project. These include those that want to switch to hydrogen once it’s available as well as those that currently emit carbon during their processes, such as energy-from-waste plant operator Viridor, which are eager to have their carbon captured and stored. “We have close to 40 industrial companies across the region that either want to consume hydrogen once it’s available or connect to HyNet’s infrastructure,” says Egan.

Undersea storage

Cheshire is not only a suitable site for HyNet owing to the amount of heavy industry in the area but its geology also lends itself very well to the project. The carbon captured both from industry and as a byproduct from HyNet’s hydrogen plants will be transported using a combination of new and existing natural gas pipelines to be stored in depleted gas reservoirs under the seabed in Liverpool Bay. The hydrogen produced at the plant, which will be built at the Stanlow manufacturing complex, will be used both as a fuel at the refinery and distributed via new hydrogen pipelines. To manage peaks in demand, hydrogen will be stored safely in underground salt caverns within Cheshire’s salt basin, a technology that is already used extensively for natural gas storage. Some of this hydrogen will eventually be blended with natural gas into the local pipeline distribution network for two million gas customers in the region.

Captured carbon will be stored in depleted gas reservoirs under the sea

“The plan is to repurpose and use existing infrastructure where we can because it’s not only more cost effective but it also comes back to the point of getting on with it to make those rapid reductions in CO2 emissions,” says Egan.

The first stage of the HyNet project includes developing the CO2 pipeline infrastructure as well as developing the hydrogen plant at Stanlow, which will initially produce 3TWh per year of low-carbon hydrogen. The front-end engineering design study of this hydrogen plant, which also includes application for planning consent, has been completed.

“We are a team of 100, who have been developing the project for a couple of years now, to a great degree of detail,” says Joe Ward, Progressive Energy’s technical project engineer on the hydrogen plant.

“Simply described, the plant takes in natural gas, which is primarily made up of methane (CH4), which is then combined with water. This ‘wet gas stream’ goes through three catalytic reaction steps, which produces a mixed stream of hydrogen and CO2. That is then passed through a carbon-capture unit which splits it into hydrogen and CO2,” he says.

Key challenge

As Ward describes, the challenges in this project are not specifically about the technology: “All of the engineering would look familiar to a chemical or mechanical engineer. It’s a gas plant, it’s catalysis, it’s compression, it’s pipes, it’s vessels… The key challenge with this project is how many organisations are involved, and combining the different technologies together.

“For instance, for the first time ever we’re trying to combine carbon capture with hydrogen production, to bolt oxygen generation straight onto a hydrogen plant, to tie a hydrogen plant into a CO2 transport and storage network and also to tie it into incoming natural gas from the grid and outgoing hydrogen. So there’s a lot of interfaces to think about,” adds Ward.

The Point of Ayr gas terminal in North Wales will be repurposed as part of the HyNet project

No discussion about hydrogen can be had without addressing ‘blue’ versus ‘green’ hydrogen. Egan argues that the correct way to think about it is blue plus green, as both are critical to reaching net zero by 2050.

There are several ways to produce low-carbon hydrogen. The two most readily available are ‘blue’ hydrogen, which is what the HyNet plants will produce in that it splits natural gas into hydrogen and CO2 that is then captured and permanently stored, and ‘green’ hydrogen, which is produced by splitting water with renewable electricity into hydrogen and oxygen. The hydrogen produced from the two processes is exactly the same but green hydrogen is preferable in that this process of electrolysis does not require fossil fuel and does not emit CO2, provided the power used is from renewable sources.

Going green

“In the long term, we all want to see green hydrogen. That’s the endgame,” confirms Egan. “But there’s challenges in getting there. Electrolysis is an expensive process that will take investment to build. Green hydrogen cannot currently be produced at large scale, not least because we do not have enough spare renewable power. This means that initially we will see more blue hydrogen as it can be delivered at far lower cost in the shorter term, and then when green comes onboard it can connect into the network infrastructure which has already been created for blue hydrogen – such as HyNet’s infrastructure.

“So it’s not one or the other, but both that we need. Arguing which is better means delays which we cannot afford.”

So blue hydrogen can be viewed as Truman’s ‘imperfect action’. Building large-scale blue hydrogen production capacity, although not a perfect solution, is a good first step that uses available technology to take a significant amount of emissions out of the economy in the near future.

In fact, as part of its first stage of development, HyNet North West aims to start decarbonisation by 2025 through both the plant and the CCS pipeline infrastructure. As the project expands, these technologies have the potential to reduce CO2 emissions by 10 million tonnes every year by 2030 – the equivalent of taking four million cars off the road.

Ward puts it another way and says: “I’m about to have my 30th birthday, and I’ve probably emitted 300 tonnes of CO2 in my lifetime. When we ‘switch on’ the first HyNet hydrogen plant, it will take my current lifetime’s carbon footprint out of the atmosphere six times every day.”

He continues: “So from day one it’ll be making a huge difference. That is exciting. It’s exactly why I became an engineer.”

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.