Not only is there the downtime required to carry out maintenance and repairs to consider, but there’s also the external damage to an asset or site caused by the gas, water or oil that has leaked. The problem is that the designs of pressure-reducing valves (PRVs) and regulators haven’t changed that much over the past 100-plus years – since the Victorian era.

Standard PRVs and regulators will typically feature a diaphragm that modulates and controls the pressure. But, to achieve constant and consistent control, flexibility is required. This is provided by elastomers and it’s these that are responsible for most PRV and regulator failures. Owing to the nature of the materials, elastomers are brittle and more prone to cracking, and, because of this, standard PRVs end up inadvertently having multiple leak paths.

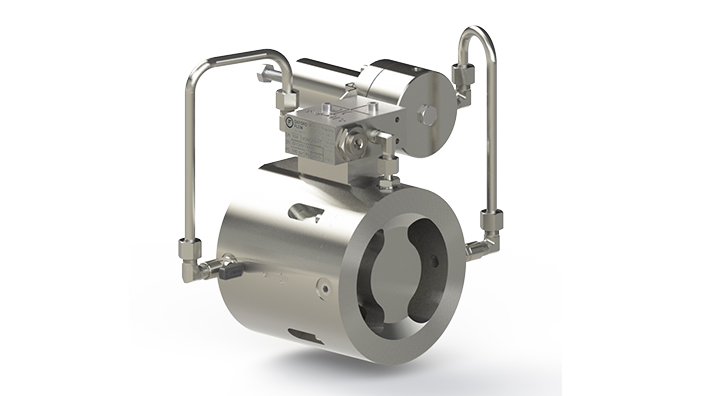

Enter Oxford Flow. The Oxford University spin-out, founded in 2015, is designing and manufacturing new types of patented, innovative water PRVs and gas pressure regulators that promise to offer improved reliability performance, increase efficiency and drive down maintenance costs. The key difference is that, instead of relying on a flexible diaphragm to control the pressure, Oxford Flow’s solution is based around a piston sensing mechanism.

When in use, the piston will move inwards or outwards when the downstream demand increases and falls respectively. This helps it to maintain a stable downstream pressure.

“We’ve removed the rubber diaphragm and also reduced the number of individual parts down from up to a hundred elements to a single moving part,” says Neil Poxon, Oxford Flow’s chief executive officer, and an industry veteran with three decades of experience, who took up the position in 2017.

He adds: “The result is a product that is lightweight and more compact, and which requires less maintenance. And less downtime for customers means they’re going to see an improvement in operational efficiency from day one.”

By designing out the diaphragm, Poxon says that the company has greatly reduced the likelihood of faults occurring. As a result, the intervals between maintenance events are much longer, leading to long-term cost savings.

Trials and applications

The idea for diaphragm-free valves was originally developed as part of research into gas turbines and jet engines at Oxford University’s Thermofluids Institute. Tom Povey, one of the company’s founders, became frustrated with market-leading pressure regulators and their inefficiency and inability to meet his R&D needs when conducting research for clients including Rolls-Royce.

One of the early adopters of Oxford Flow’s pressure control technology was Veolia. The water company’s mobile division, which provides on-site water purification services, realised that delivering pressure to customers was a fine balancing act. Too much and it would cause damage to their assets; too little and it would mean the water wouldn’t be purified.

Oxford Flow’s technology, however, meant Veolia could meet differentiations in pressure and varying flow rates. The lightweight nature of the products, which is mainly down to the acetyl resin they’re made from, makes them ideal for mobile and off-site operations. Weighing around 4kg – 80 to 90% of the weight of standard PRVs and regulators – means that no heavy machinery or lifting equipment, which can be expensive to hire, are required during installation or repairs. In turn, this allows for easy transport and rapid deployment, which can be especially useful when responding to critical and emergency maintenance events.

Keep the water running

Another utility that has benefited from the PRV technology is Northumbrian Water. Distributing water to homes and businesses is a critical task. Any utility needs to not only ensure that there’s enough water available to meet demand at peak times but also make sure that pressure is never too high or too low. Failure to do this can result in leaks and disrupt day-to-day life for thousands of people.

While the reported number of properties Northumbrian Water supplies experiencing leaks has been dropping over the past few years – that’s according to the company’s annual report for the year ending March 2018 – it decided it could offer an even more reliable service and so it adopted Oxford Flow’s PRVs.

According to Poxon, the savings a water company will see may seem marginal when taking into account one of its PRVs in isolation. But when you factor in that a whole network of them is required to keep the water flowing out of taps, the reduction in costs becomes far more significant.

Earlier this year, Oxford Flow announced that its first hydrocarbon application trial, with the gas distributor SGN, was under way. SGN’s aim is to improve how it performs in distributing natural and green gases to its network of 5.9m homes and businesses in the south of England and across Scotland.

In July, Oxford Flow revealed that its regulators had demonstrated that they could manage pressure efficiently, to within 1.5% of the target level. In comparison, standard regulators manage to get to within 5% of the intended gas pressure level.

Oxford Flow's gas regulator

“The trials are nearing completion and we expect to achieve the required Ofgem product approval [for the IM Series gas pressure regulator] by the end of the year,” says Poxon. “Once this is in place, we can then start selling to the UK’s gas distribution network and further afield.

“As for the water industry, we’re in a very strong position, with most of the UK’s water utilities having at least one of our PRVs installed. We’ve also seen significant sales across four continents and have several other innovative flow solution concepts in the pipeline.”

Commercialisation

As with any engineering company, taking a product from the trial stage to commercialising it requires a broad range of specific skills, knowledge and expertise. With the help of funding, Oxford Flow has been able to build a team of mechanical and production engineers and intellectual property specialists to help take its products forward to the commercialisation stage. In 2018, the company raised more than £6m capital, including from Oxford University, Oxford Sciences Innovation and the Institution of Mechanical Engineers.

Speaking about the support the company has received from the Institution’s Stephenson Fund specifically, Poxon explains that it has helped in the recent expansion of all areas.

“From hiring bright young talent to welcoming seasoned professionals, we’ve added 10 people at our Oxford headquarters in the last year, taking the total number of employees to a couple of dozen,” he says. “We’ve also used the investment to drive our R&D work. This includes the development and installation of cutting-edge testing equipment and facilities.”

To accommodate the growth, Oxford Flow recently expanded its office space to more than double the size. It also has plans to increase its headcount further, to more than 40 employees.

This move, says Poxon, will be critical as the company looks to future-proof and “advance the time to market for our various offerings and accelerate the deployment of the flow control valve technology, especially into other markets worldwide”.

Key facts about Oxford Flow

- Founded in 2015

- Inspired by research into heat transfer in jet engines

- Backed by Oxford Sciences Innovation, an investment company dedicated to deep science and technology that specialises in scaling-up Oxford University spin-outs

- No diaphragm means fewer faults and leaks and reduced maintenance costs

- Lightweight – around a tenth of the weight of standard pressure valves

- Ideal for water and gas distribution

- Other industries that could benefit from the technology include food and drink, marine and construction

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.