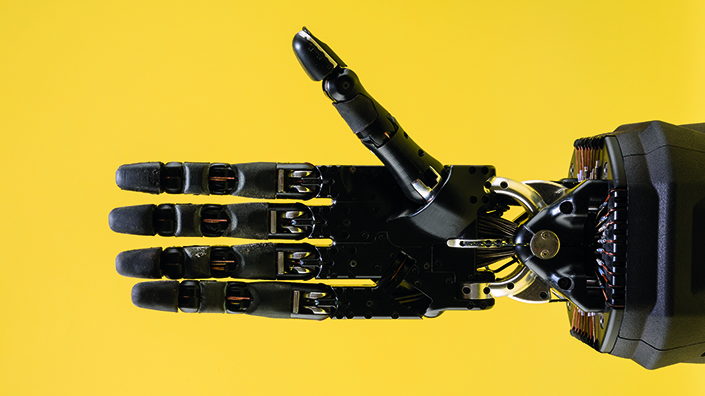

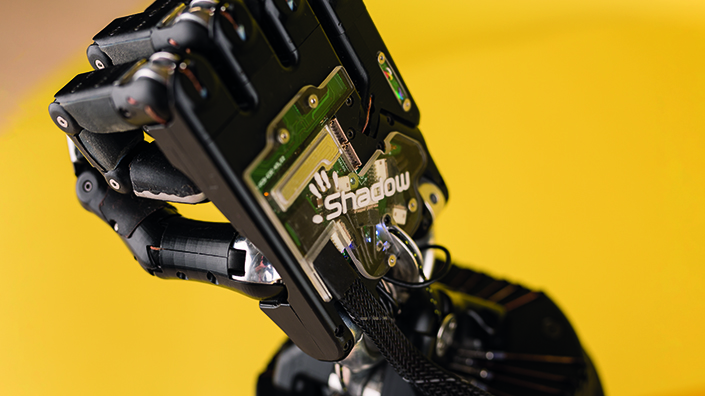

OK, it’s not nuclear waste, it’s Quality Street – but it still feels like an achievement. The metal hand copying my movements is attached to a robotic arm swivelling on a table to my right. The hand is sleek, life-size, black and has some exposed workings. A few black wires feed into it, and the ‘wrist’ is a bulky black box. Its movements are in turn surprisingly delicate and swift. It whirs gently.

The nuclear decommissioning simulation I am doing feels straight out of science fiction, but it is remarkably close to real-world applications for the advanced machine – and there is increasing demand for such cutting-edge technology. In its quest for knowledge, energy and money, humankind has gone to the depths of the ocean and the void of space. It has poisoned the environment through mismanagement of the most toxic materials, putting nature and people at risk.

Now, we need a hand.

Reaching out

Of all the streets in London, Gordon House Road hardly seems the most likely to contain this extraordinary, potentially transformative technology. The office building housing the Shadow Robot Company is opposite a quiet Victorian terrace, a stone’s throw from Hampstead Heath. Opened last year, it is London’s first robot factory.

Managing director Rich Walker runs through everything, jumping topics – control systems, cobots, Milo the office dog, the company’s hobbyist history. The journey that led to the dextrous hand started more than 30 years ago, but the company’s engineers are still very much enthusiasts. Founder Richard Greenhill wanted to see robots “everywhere”, says Walker, and that remains a driving force.

“We’re in this because we want to do it, not because we see a quick win, an opportunity to IPO [initial public offering] and cash out or something. It’s actually that we like doing this stuff and we want to do it, and we’re in it for the long haul.”

This approach partially explains why progress might seem slow from the outside. A proudly displayed Professional Engineering cover from 10 years ago, for example, shows a Shadow hand that – at first glance at least – does not look too different from today’s version.

Mechanical upgrades since then, such as the one from pneumatics to motorised tendons, were not predicated on the latest technological breakthrough. “There wasn’t a particular change, it was just an architectural decision to make a motor version rather than a pneumatic version,” says Walker. “We could have done it at any point, we just hadn’t got around to doing it.”

It would be all too easy to downplay the technical progress made, however. The latest anthropomorphic device faithfully recreates the complex kinematics and dexterity of the human hand, with full degrees of freedom. It has 24 joints driven by 20 motors, with two tendons per joint – one for straightening, one for bending, just like real fingers. The machine includes 40 strain gauges, 25 temperature sensors, and pressure sensors on each fingertip. Operators control it by standing in front of motion-sensing cameras, wearing a specialised glove and a wrist tracker for the system to track and replicate movement.

It is an amalgamation of some of the most amazing modern technology that we take for granted. Cheap mobile-phone cameras, 3D vision systems and low-cost processing all played a part, says Walker, while the rise of industrial cobots has opened up new operational possibilities.

Of course, the hand is just that, and extends no further than the bulky box housing the tendon motors. It relies on integration with other technology, such as the Universal Robots arm in the office. This will be an increasing focus as the company explores more industrial scenarios or operation in confined spaces, says Walker. It will be a key step as the hand reaches out into some of the most inhospitable environments on Earth and beyond.

From Gospel Oak to orbit

People have dreamed of teleoperation – remote control – of human-like machines for decades, and Shadow recently made it reality. As a demonstration, an operator in California accurately controlled the hand in London’s Gospel Oak, 5,000 miles away. Even more remarkably, the operator could feel the sensation of the robot hand touching an object, thanks to the device’s SynTouch pressure sensors and a HaptX haptic feedback glove.

The fantastic achievement was no doubt welcomed by Japanese space agency Jaxa and airline ANA, which are collaborating on one of the most ambitious space missions in development.

The forward-looking Avatar X project aims to develop avatar technology for space exploration and colonisation. Why put a human in space, the argument goes, if it is more expensive, more dangerous and less efficient than launching a robot? As humanity builds more space stations and even lunar or Martian bases, Jaxa and ANA believe that partially humanoid robots known as avatars can lay the groundwork – while people on Earth stay in control.

“If we sent a single high-performance avatar to space, we would then be able to use it to call upon any human skill in the world when needed,” says Kevin Kajitani, manager of the avatar division at ANA. “We believe this is the safest, most efficient way to accelerate space exploration and development.”

He adds: “Avatars are not a replacement of human effort and skill but an extension of it. Using avatars will allow any human to easily access space and leverage their skillset for whatever it’s needed for.”

The project, which is identifying the most promising applications and “making those a reality”, is working with Shadow.

“Through the various Avatar initiatives that I run, I’ve seen and demonstrated a lot of technology,” says Kajitani. “Shadow is the most advanced dextrous robot hand that I have seen. Being able to manipulate and impact a remote environment is critical for space applications – it’s not that useful to just exist in space without any ability to turn knobs, flip switches and perform experiments. That’s why we believe their technology has a high synergy with space-based avatar applications.”

That multi-functionality is key to another of the major possible advantages – weight. Depending on the launcher, each kilogram of payload can cost several thousand pounds to send into orbit, so any ability to cut mass is welcome. If a versatile robotic hand replaces several other devices, it could save money or enable more ambitious missions, such as construction of ‘mega-constellations’ with hundreds or thousands of satellites.

Jaxa and ANA hope Avatar X will lead to much more than just construction, however. Other tasks include teleoperation for space-station maintenance, and even remote travel in space for tourists.

There is an almost childlike glee to Shadow’s application in space, says Walker – put the newest kit in the most exciting arena. But for some sectors using robots is not a cool idea, it’s a pressing need.

Radioactive plan

Nuclear decommissioning is, as the National Centre for Nuclear Robotics (NCNR) recently highlighted at the Royal Academy of Engineering, a massive headache (see Reaction, Professional Engineering No 4, 2019). The huge investment and time needed to clear up increasing amounts of nuclear waste in the UK is mirrored around the world, and the problem is growing.

The task “has been gathering steam in recent years, particularly because of the age of plants that have been deployed in the 1950s and 60s. There is a huge market, globally and locally,” says Nikos Pronios, innovation leader in robotics and autonomous systems at Innovate UK.

Safety concerns put a hard limit on the amount of time humans can spend cutting up and disposing of irradiated material, and so the industry is turning to robotics. Drones can scout huge areas, such as the NCNR and University of Bristol’s recent radiation mapping of the irradiated Red Forest in Chernobyl. Small, tank-like robots might be best for negotiating uneven terrain and mapping out closed-off, contaminated areas. But, if dexterity is needed, Shadow could provide it.

“Is the dexterity of this the challenge… or is it that you want brute force, a man with a spanner pushing really hard on something? If it’s dexterity, then let’s see how we can turn the hand into something we can use,” says Walker.

Shadow recently took part in the Alpha Glovebox Decommissioning Challenge, aimed at reducing risk and increasing efficiency during the decommissioning of alpha-contaminated ‘glovebox’ cabinets at Sellafield, which kept workers separated from nuclear material. The project, led by Innovate UK and UK Research and Innovation, explored advanced options to replace manual work and simple teleoperation. The London company used its technology to grasp and move nuclear objects, comparing collected data with other simulations.

Using robots in nuclear environments depends on four criteria, says Pronios – cost, efficiency, time and safety. Robots still face radiation damage but the risk is not comparable to the danger for humans, and does not result in the same cumulative pile-up of new nuclear waste in the form of countless gloves and suits.

Superpowered

Exciting new capabilities could open up even more opportunities in future – why stick to life-sized hands, for example? A human operator could be just as familiar with an Ant-Man-style miniature device or a more Hulk-sized giant fist, if controlled in the same way.

Anthropomorphic hands will not just be limited to use on fixed robotic arms, says David Bisset, who works with the Department for Business, Energy and Industrial Strategy to develop robotics in the UK. One promising future area he predicts is mounting the Shadow dextrous hand or similar technology on drones.

Unmanned inspection aircraft, for example, need stability and even contact with the surface of structures to get clear images in hazardous environments. A teleoperated Shadow hand on a drone over the horizon could carry out maintenance on distant structures such as chimneys or turbines, something that is not yet possible. “That’s clearly a real future step,” says Bisset. More applications in energy, including tasks such as oil and gas decommissioning, could become prevalent in future.

Not all advanced technologies will easily be implemented with the Shadow hand – “it’s going to be a while” before an AI-controlled device is as dextrous as a person for complex tasks, Bisset predicts – but the company’s partnerships with research labs around the world will undoubtedly lead to exciting possibilities beyond decommissioning, building, maintenance and human interaction.

At the Shadow Robot Company, says Walker, they ask themselves: “Where is the baseline, what is the best you can do in the world today?” The company believes it has built that baseline. “We have this bit – what can you do next?”

Read part two, "Does a robot hand need to look like a human one?", here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.