'Never make another uninformed decision'

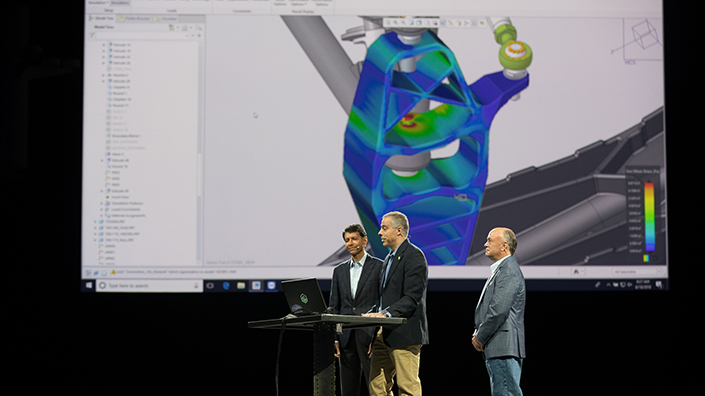

A PTC engineer demonstrates the CAD-simulation tool at LiveWorx (Credit: PTC)

Design has always been a long, costly process. Even if you put weeks of work into a component, one failed test can throw it back to the drawing board.

CAD software revolutionised the process roughly 50 years ago, transforming flat pencil lines into 3D, knowable shapes. More recently, complex simulation software meant you could test components for strength, fluid flow and other parameters before building them. But still, design and simulation were separate and transferring models from one program to another was time-consuming – until now.

That was the sell, at least, for PTC’s first big announcement of the conference – a collaboration with simulation specialist Ansys. In the autumn, Ansys’s Discovery Live tool will combine with PTC’s Creo 3D CAD software. The resulting program will be the first to feature live simulation of stresses on parts, said the companies.

“Speed of thought” will be the only limit on quick innovation, they claimed. Design engineers will instantly receive structural, thermal and modal simulation feedback for designs, letting them react immediately.

A “giddy” PTC engineer demonstrated the tool on stage in front of thousands of conference attendees. Opening a CAD model of a snowmobile, he activated the simulation on a key loadbearing part linking a blade with the main body of the vehicle. Red bands near the top showed dangerous pressures on the vital component. He then simulated movement on the part, showing it vibrate and sway unnervingly.

The engineer quickly reacted to the rainbow-coloured stress lines, adding in a cross-support. The stresses instantaneously disappeared on most of the component.

The technique promises a reduction in trial-and-error, letting engineers find and eliminate problems early in the process and reducing costly, lengthy delays.

As well as instant simulations, decisions will also be augmented by powerful artificial intelligence. PTC president Jim Heppelmann revealed the Creo 5 software on stage, including a ‘generative design’ element (see In the Know, PE March). The process mimics evolution to create optimised designs with strange, organic-looking shapes.

“Having Mother Nature at your side really changes everything,” said Heppelmann.

'We want to go fast'

William Gerstenmaier on stage at LiveWorx (Credit: PTC)

William Gerstenmaier received a lifetime achievement award for innovation before his stage discussion at LiveWorx. But the associate administrator for human exploration and operations at NASA was in no mood for navel gazing. Instead, he drew upon his 41 years of agency experience to look forward to some of the biggest challenges and opportunities in space.

Vehicles need faster electric propulsion for human exploration further into the solar system, he said. “We can’t go faster than the speed of light – but we want to go fast.”

Although chemical fuels give much stronger thrust than electric propulsion, fuel tanks are prone to emptying over the course of long voyages. Instead, Gerstenmaier called for more development of solar- and nuclear-powered electric propulsion, which can accelerate constantly over long distances to reach dizzying speeds.

Working in space gives new capabilities alongside a new perspective, said Gerstenmaier. Additive manufacturing is unconstrained by gravity, allowing operators to experiment – not needing to add strengthening starch for replacement heart valves, for example.

The technique will also revolutionise space travel by letting astronauts print replacement parts on demand. “As we break the tie with the home planet and we move out, we can’t take every piece we need,” he said. “It’s opened up a whole new way of looking at new things that we can build in space.”

Gerstenmaier confidently predicted major innovations in the coming years. With a constantly shifting balance between public and private organisations, however, they will appear in a different landscape.

“The neat thing about space is it’s the ultimate team experience,” he said. “You need everyone to contribute. We’re trying to figure out how we work with all those companies to build our next-generation spacecraft.”

Fly into a new reality

The AR application shows airflow over the Cirrus plane's wings in Vuforia Studio (Credit: Joseph Flaig)

I’m looking at the plane in real life, and on a tablet being held in front of me. Looking ahead, the Cirrus business jet is everything you would expect for something costing $2m – sleek, comfortable and beige on the inside.

On the screen, however, it looks altogether more dazzling. Vibrant multi-coloured bands flow gently above the wings and fuselage, revealing the invisible airflow over the aircraft in simulated flight. A purple band shows fast flow over the wing – just as you would hope – which quickly slows down and spreads out in its wake.

The augmented-reality proof of concept is one of three developed for Cirrus by PTC on its Vuforia Studio platform. The second is a simple pre-flight walk-through for the largely executive owners, while the third uses model tracking to reveal complex systems beneath the surface, animating them for training purposes. A pressurised air system funnels bleed air from the engine through a heat exchanger, while Cirrus’s famous four-point plane parachute springs out from the roof, ready to deposit oligarchs, pro athletes and other pilots on the ground with their aircraft intact.

The simulated airflow is perhaps the most technical-looking application, but at the moment it only shows a standard flying scenario. In future, said engineer Dan Mittelstadt, it could demonstrate different situations to potential operators.

“If you could illustrate to the operator the stall scenario and why it occurs, you can more effectively communicate the behaviour of the aircraft,” he said.

Roaming robots cross the floor

The Hirotec robot uses two arms to pick up heavy boxes of materials and move them to where humans need them to be (Credit: PTC)

Mobile industrial robots are finally finding their place on the factory floor. In LiveWorx’s ambitious working replica of a smart factory, a Hirotec machine was a key part of the production line. Internet of Things-connected scales under boxes of materials told the machine when they were full, prompting it to pick them up with two arms and ferry them to the next human worker in the chain.

Elsewhere, Waypoint Robotics was a popular stop for visitors. The company’s autonomous mule robot slid across the conference floor on Mecanum wheels, similar to conventional wheels but with angled rollers around the rim. The wheels allowed the robot to follow the most efficient paths gracefully and quickly, while carrying up to 136kg.

The Mecanum wheels are slightly more stable, but Waypoint’s co-founder and chief executive Jason Walker said a main draw for customers is that they allow the machine to make minute adjustments during journeys. They also allow complicated paths that would be difficult with conventional swivelling castors. He said: “A lot of our customers need to be able to strafe up to a machine, or a conveyor or something like that, to avoid having to reconfigure their manufacturing operation or move machines around.”

Critical threat to medical devices

.jpg?sfvrsn=11e4b612_0)

The conference floor at LiveWorx (Credit: PTC)

“Healthcare cyber-security is in a critical condition.” As opening remarks go, it’s certainly one that grabs attention.

While hospitals face the perilous threat of malicious cyber-attacks, companies are busy creating advanced biomedical devices that could offer even more routes in for hackers motivated by national, financial or extremist interests. A panel of experts from conference host PTC, the US Food and Drug Administration and healthcare workers debated whether all patients are at risk.

“Whether it’s an individual patient with a pacemaker or an insulin pump, or whether it’s the care they receive hooked up to a bedside diffusion pump, there is a large volume and variety of cyber-security vulnerabilities being found,” said Josh Harman, PTC’s chief security officer.

A report from Allied Market Research concluded that the market for medical Internet of Things (IoT) devices will grow from $60bn in 2014 to $136bn by 2021. Advanced analytical software is combining with internet-enabled health monitors to provide constant feedback on patients’ conditions.

Researchers are also developing ‘smart’ devices to improve care and treatment, such as advanced human-machine interfaces or miniature robots that travel inside the body.

“IoT represents a great opportunity to provide better outcomes,” said Ken Herold, manager of application security at PTC. “But that’ll also present additional opportunities for adversaries to hit the devices as they move from a clinical setting into a homecare setting.”

Companies should let ethical hackers check for vulnerabilities on new biomedical devices before patients’ lives are put at risk, said ‘biohacker’ Nina Alli.

“We’re promoting that they start looking at it from a different way,” she told PE in the conference’s cyber-safety ‘village’. “Call the hackers in, call the hackers who are going to look at it anyway… and say ‘Let’s work on it together’.”

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.