Biomass can get a bad press. The very idea of burning trees to produce power can send some environmentalists into a tizzy. Add into the mix the fact that a tree felled in South America is shipped across the world to be burned, and that industry says biomass provides a renewable, low-carbon source of power, and the result is a frenzy of protest.

But the reality is that the age of biomass will soon be upon us. The UK’s largest coal-fired power plant is already being converted to run on the stuff. Environmental legislation is calling a day on older coal-fired power stations, and other renewable technologies are not yet producing power on the scale that we need to replace them, so biomass could help to plug the gap.

The country needs to get carbon emissions down quickly and converting coal plants to run on biomass is one way to do it, says Dr Patricia Thornley, senior research fellow at the Tyndall Centre for Climate Change Research. “We have a big fleet of coal-fired power stations. If we can maximise the use of biomass in those, that goes a long way to getting carbon reductions in the near term,” she says.

Under the Climate Act 2008, the UK is legally bound to reduce greenhouse gas emissions by 90%, based on 1990 levels, by 2050. A range of measures will be needed to meet the target – if indeed it is possible – including the conversion of power plants that were originally designed to burn coal to take biomass. But the modification of decades-old plants brings a unique set of challenges.

Many plants up and down the country have been burning biomass alongside coal for years. Indeed, all 16 of the major plants now do this. With this “co-firing”, 10-20% of the feedstock to a coal power station is made up of wood pellets.

Different power stations have adapted to co-firing in different ways, but essentially it involves combining biomass with coal. The biomass is first pelletised, then ground into a fine powder alongside coal in the existing mills at the plants. It can be burnt in the same way as the coal without detrimental effects on boiler tubes and internal combustion equipment.

But these modifications will take co-firing only so far. Increasing the proportion of biomass above 20% requires more radical engineering changes to deal with its different characteristics. Biomass has higher volatiles, for example, so the combustion unit needs to be reconfigured to cope with this.

Meanwhile, critics say that the partial conversion of existing coal plants to use biomass is giving a lifeline to the ailing coal industry, which collects subsidies from the government in exchange for using renewable fuel. “In some cases, the coal-fired plants wouldn’t continue to be economically viable were they not able to get the renewable obligation certificates for the biomass,” says Thornley. However, there is not enough capacity in the generating system to survive without these plants. “We need those plants to be continuing, and if we can get them to continue with a lower carbon intensity, that is a good idea,” she adds.

Another biomass option has been purpose-built plants. Dedicated plants can take a wider range of biomass, including forest residues, but they cost money to build. There can also be difficulties in getting planning consent and the permits that are needed to run a power station. Existing facilities already have these in place, as well as the transport links required to bring in feedstock.

Given all these factors, it is cheaper to convert an established coal plant to run on biomass than to build an equivalent new one, Thornley believes.

Some of the big energy companies agree. At Drax, the UK’s largest power station, in Selby, North Yorkshire, an ambitious project is under way to convert three of the six generating units to run solely on biomass.

Conversion of the first unit is well advanced, and this switched to operate on pure biomass in early April. Engineers are still tweaking the mechanisms within the generating unit that enable it to run on biomass, while work continues to get the new fuel storage and handling facilities up to scale to serve half of the plant. The second generating unit is due to switch to biomass in 2014, and the third in the following two years.

“If Drax has a future, it has to move away from coal,” says Peter Emery, production director at the power station. “For us, this project is a way to innovate away from economic extinction.”

The advent of the carbon tax increases the pressure, he adds. “The new carbon tax came in from 1 April, and that is going to escalate over the next 10-15 years. Our view is that this will quickly make coal a marginal fuel in the UK energy mix.”

In 2005, the company developed a strategy that would decarbonise power generation. Top of the list was improving the efficiency of the plant to reduce carbon emissions overall. Work began immediately on a £100 million project with Siemens to upgrade the high- and low-pressure turbines at the station. This project was completed last year.

At the same time, longer-term options to reduce emissions through carbon capture and storage were looked at, and work continued to replace coal with a low-carbon fuel.

Drax had already been working with small quantities of biomass. In 2003-4, it was firing 50,000 tonnes a year alongside coal. By 2006-7, this figure had ramped up to 250,000 tonnes. But it then became clear that, to make a step change in co-firing, the power station would need to invest in bespoke facilities. By engineering and commissioning a new direct-injection co-firing mechanism, the company was able to boost the biomass contribution to 1.5-2 million tonnes a year – around 15% biomass on each of the station’s six units.

The plan was to develop the co-firing capacity of each unit further to 50%, but a sudden change in government policy in 2011 turned the project on its head. The coalition, which had supported biomass co-firing when it first came to power, decided to back full conversion of existing stations to biomass. At Drax, the news caused an “engineering headache”, says Emery, because work on the project to boost co-firing had already started.

Plans for the facility to receive fuel by rail and develop storage units did not need to be changed too radically – switching to 100% biomass on three of six generating units requires the same volume of biomass as converting all units to run on 50%. But the engineering of a new fuel distribution system and conversion process had to be fast-tracked, says Emery.

The biggest challenge was upping the quantity of biomass to be burned to 100% of fuel, he says. The calorific value of the material is two-thirds that of coal, so more must be burned to give the same output.

“The concept inside the boiler has changed dramatically, and we had limited time to prove this last year before we designed the project, so there is a lot of optimisation going on,” he says.

In the unit that is up and running, the flame detection system is still being tweaked. “That is an important safety feature. You do not want to be introducing fuel into a furnace where there is incomplete combustion, as this leads to fires and explosions,” he says. The system is being adapted to detect a biomass flame, which differs from a coal flame.

A set of biomass burners is in place, but the technology is relatively new and engineers are still testing several types of burner for full combustion and a stable flame. Work is ongoing to optimise the air flow through the burners, and a boosted over fire air system has been designed to help control nitrogen oxide emissions.

Managing how biomass burns is proving tricky. “Biomass tends to burn more slowly than coal, so we get higher temperatures at the back of the furnace,” says Emery. “Secondly, biomass can vary – it has elements such as alkaline metals, chlorine and silica, and they can cause fouling.” The performance of a fouled furnace falls quickly, so Drax is working to manage fuel quality and include additives that can mitigate fouling and corrosion.

Outside the furnace, there are other challenges. More biomass is needed to produce each unit of energy compared with coal. “It is two-thirds of the bulk density – if you do the maths, you are handling broadly double the volume,” he says. The additional material has to be handled and stored.

Unlike coal, biomass swells to three times its size when wet and cannot then be burned, so covered storage has had to be designed and built. By contrast, coal at Drax is stored in open stacks. The biomass tends to be very dry and produces a lot of dust, which can cause problems. Biomass will self-heat, just as a compost heap does, and can ignite. Even relatively small piles of biomass dust can self-heat, leading to an explosion risk. So it needs to be monitored and managed in a way that is not required with coal. “You do have similar issues with coal dust, but far less because coal is quite wet when you introduce it to the mills. It’s harder to ignite in smaller quantities,” says Emery.

The dust is hazardous and, unless the biomass is completely enclosed, will pose a health risk to operators. “From an operational perspective, you have to treat biomass with even more respect than coal,” he says.

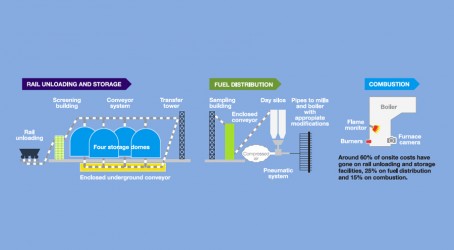

As part of the conversion, the rail unloading and storage system has been redesigned to minimise dust production. The conveyors are fully enclosed, and the system has new transfer points in an attempt to minimise the physical impact on the biomass every time it moves from conveyor to conveyor. The storage domes that will house the biomass are designed to minimise and contain any dust. Where possible, low-heat lighting is used to remove potential sources of ignition. From the storage domes, the biomass travels in a fully enclosed system to day silos, where it is transferred to a pneumatic system that takes it by pipe to the generating unit. The biomass is milled and injected by blowers into the unit. At the moment, the existing direct-injection facilities are in use, but a new system is being commissioned. “That is a massive change from how we treat coal,” says Emery. In coal units, the fuel passes through a series of bunkers before it is milled and blown into the burners.

Across the project, the business has taken “some leaps of faith” to deploy the new technology, he says. The output of the units that run on pure biomass will be 585MW, around 10% less than the units that run on coal, but work will continue to improve that. The unit operating on pure biomass has an 80% reduction in carbon emissions compared with those that take coal, he says.

Converting the station will not come cheap. Drax is spending £300 million on-site alone. Up to 1,000 contractors will be on the site for almost 18 months to achieve the transformation. The same sum again will be spent to develop pellet plants in Louisiana and Mississippi, and a port facility in Baton Rouge, so the biomass can be shipped to Drax. The business has also secured biomass from elsewhere in North America, the Baltics, Europe and Africa. But more is still needed.

Sourcing enough biomass for the project has been tough, says Emery. “It’s a little bit ‘chicken-and-egg’, because people don’t want to commit to pellet plants if they are not convinced you can stand behind a longer-term contract, and we can’t justify converting the station until we have got a secure supply of pellets.”

The biomass supply industry is still in its infancy, but looks set for growth. Up and down the country, many coal-fired plants are running on limited time and are set to close under the large combustion plant directive (LCPD) – legislation designed to control acidification, ground-level ozone and particle pollution across Europe by reducing nitrogen and sulphur oxides and ash emissions from large power plants. Converting the stations to run on 100% biomass may prove an appealing option. RWE has converted its plant in Tilbury in Essex to run on pure biomass (see box, above). The plant had been scheduled to close under the LCPD, but RWE is now looking to extend its life for a further 10-12 years.

So far, the plans of other operators are less advanced than those of Drax and RWE. E.On is considering converting its Ironbridge plant to run on pure biomass, as is Eggborough Power, which runs a 2,000MW plant in North Yorkshire. Both companies declined to comment on progress for this article.

Benefits add up despite thousands of shipping miles involved

Exactly how green are biomass power plants, given that their fuel comes from forests that are vital to the earth’s carbon cycles? After trees are chopped down and processed, the biomass is then often shipped halfway around the world for burning. But if forests are properly managed, biomass is a credible source of renewable energy, says Dr Patricia Thornley, senior research fellow at the Tyndall Centre for Climate Change Research.

She has calculated the carbon footprint for several biomass systems and says the carbon reductions for electricity plants are in the order of 80% lower than the UK grid average. The carbon reduction benefits are less if the biomass needs substantial processing, such as pelletising. Pelletising brings the carbon reduction benefits to 60-70% less than the UK grid average, she says.

How far the biomass travels to reach the plant, and how it is transported, are other factors in determining the carbon footprint. But the effect of transporting the fuel thousands of miles is not as large as people might think, she says. “Shipping is really efficient and doesn’t actually have that big an impact on the carbon footprint.”

One of the biggest issues to come to light recently is how changing land use to grow biomass crops can alter the dynamics of carbon exchange in the atmosphere. The impact of land use change needs to be accounted for in calculations, and this is not straightforward. “Taking into account the carbon all the way upstream is incredibly difficult,” she says.

“The government is trying to be sure that the biomass that we are using is having carbon benefits. It is putting effort into getting the certification in place and getting it right,” she adds.

Research is ongoing into how the carbon balance of ecosystems might be affected by changes in forestry patterns and land use, but Thornley says she is happy with the biomass that is coming into the UK. “The vast majority of it is delivering carbon reduction benefits compared with what we have on the national grid.”

Full conversion cuts emissions at Tilbury B

RWE converted its Tilbury B power station in Essex to run on 100% biomass fuel in 2011, saying that this option was many times cheaper, and less time-consuming, than building anew. Previously, the plant had been co-firing coal and biomass for seven years. The switch to pure biomass has reduced greenhouse gas by more than 70% compared with coal, as well as reducing nitrogen and sulphur oxide emissions and ash, says the company.

The power station uses wood pellets that are mostly sourced from the south-eastern US or Canada, with some coming from RWE’s own plant in Georgia, and that are shipped to the UK.

The engineering behind the conversion took just four months, says RWE. Switching to biomass required modifications to the mills and classifiers to accommodate the fuel, because the pellets have a different diameter from coal. Engineers modified the burners to optimise combustion and improve the stability of the flame.

The main challenges were the handling, storage, maintenance and transfer of the biomass, says the company. To reduce escaping dust when the wood pellets are being unloaded from ships, it has installed two dust-suppressing vacuum unloaders.

RWE has planning permission to convert Lynemouth power station in Northumberland to run on biomass, but has yet to make a decision on when the conversion will happen.