Engineering news

The fibres, created with chitin nanoparticles from residual blue crab shells and alginate from seaweed, were developed by a team from Aalto University in Finland, the University of São Paulo in Brazil and the University of British Columbia in Canada.

Chitin is well-known for its antimicrobial properties, while seaweed alginate forms strong gels. To extract the materials, the researchers converted alginic acid from brown algae cell walls into sodium alginate and dissolved it in water. Blue crab shells were ground and purified then partially deacetylated using simple procedures.

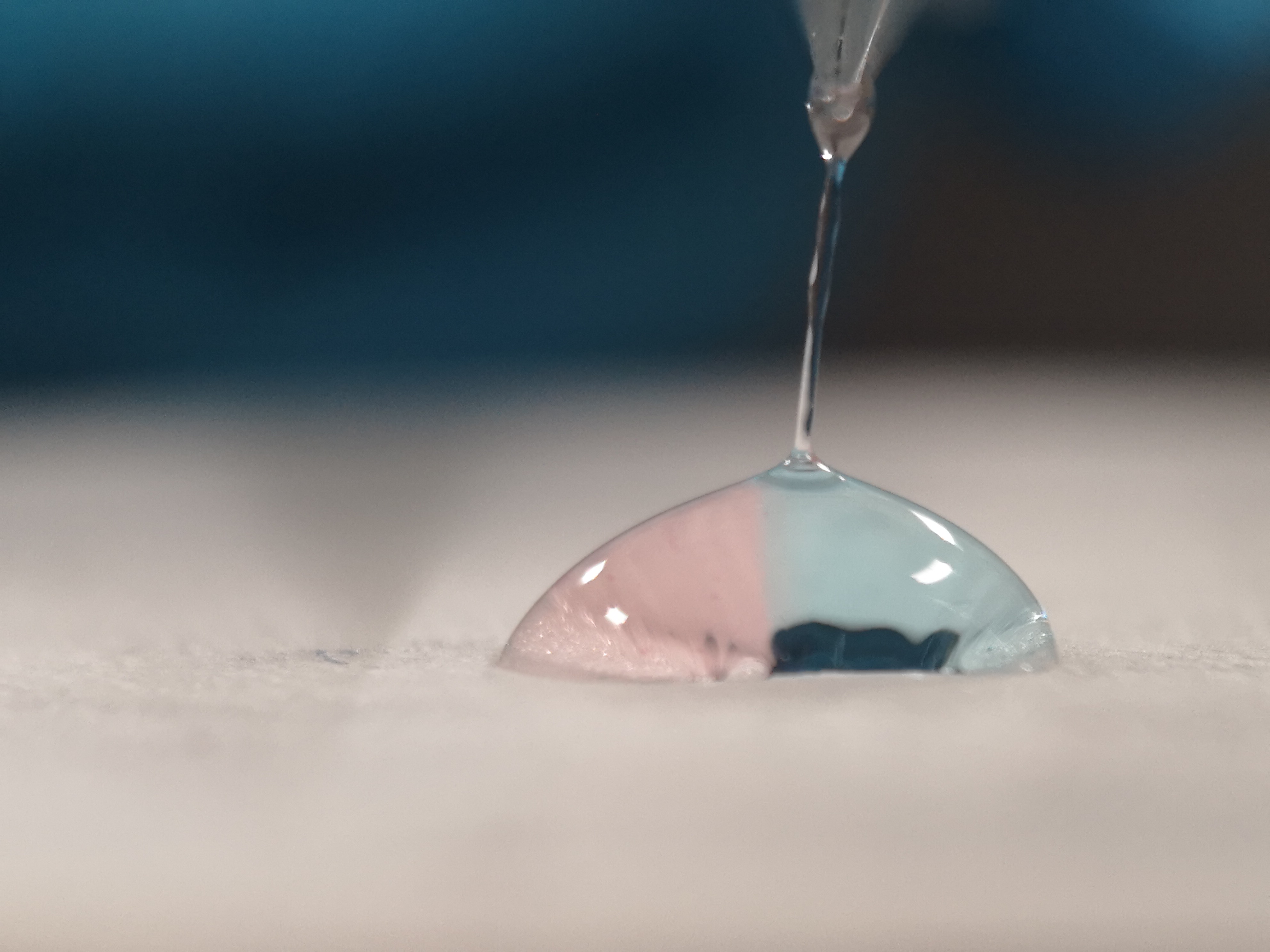

A video shows researchers placing drops of the materials next to each other before gently bringing them together with a tweezer-like tool. The implement is then lifted, drawing a fibre of the new material upwards.

A thread of the new material is drawn upwards (Credit: Aalto University)

“The designed material took advantage of the strong interaction between the components, which are oppositely charged,” said Professor Orlando Rojas from Aalto University. “We found that when a solution of alginate contacts a suspension of chitin nanofibres, the alginate wraps around the chitin nanoparticles, forming fibrils that align in parallel as the thread is drawn upward.”

The material could potentially be used as threads for surgical procedures and webs for internal tissue engineering. Other uses include pads and web-like meshes for wound healing, skin conditioning and burn treatments.

“It's a well-known fact that chitin nanoparticles are antimicrobial and bioactive,” said Professor Rojas. “For example, they have shown to help hair growth.”

The team studied how differences in the concentration of each component, the size of the nanoparticles and other variables affected the mechanical properties and ‘spinnability’ of the final threads, helping to produce strong, flexible threads continuously.

The researchers hope to scale up production by using "simultaneous microfibre dry-drawing" from the suspensions.

The work was published in ACS Sustainable Chemistry & Engineering.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.