Formula Student

GKN Automotive Innovation Centre in Abingdon has been able to support Nottingham FS team achieve their goals in various ways, including testing out their drives using GKN Automotive’s facilities with 4 different test cells - one of them having a high power (350kW), 2 wheel (both driveshafts at wheel speed) eDrive rig.

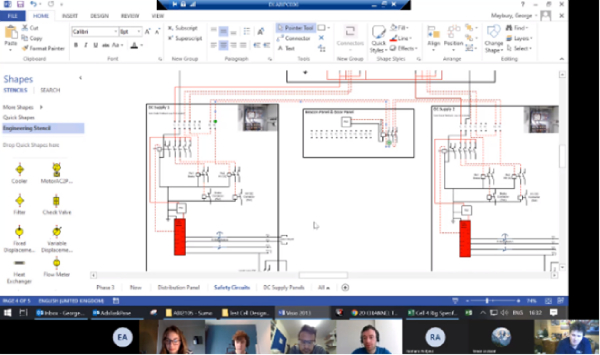

Having missed out on the 2019 and 2020 seasons, Nottingham was very determined to put in the work in order to achieve their targets. However, with Covid-19, access to the GKN Automotive Innovation Centre site was restricted. This did not deter the Team and they made best use of remote working to tap into the engineering expertise at their disposal:

- They took advantage of the organised wiring training for their harnesses to enhance their skills

- They used the centre’s ability to monitor tests remotely to reduce numbers on site, whilst getting valuable input into rig assembly, inverter diagnosis and tests, motor and gearbox tests and results analysis.

The team was able to replicate endurance tests to identify whether their drives would last the whole cycle without overheating and to make the adjustments required. They also looked at thermal stability to ensure that all potential heat points were identified and torque control.

“Having this opportunity to set up the dyno rig tests with the guys at GKN was a brilliant experience," said Surojit Sen, Technical Lead Electrical and Electronics for the team. "A lot of potential issues were unearthed during these tests which may have otherwise been overlooked. We were also able to extract more torque and power than we were expecting to, thanks to the clever tuning done on the inverters. All of us at UoN Racing Team have come out a bit smarter and wiser from this collaboration and would endeavour to carry on this upwards trend.”

But the sponsorship with UoN and other FS teams is not all one sided. Some of the problem solving has been transposed to in-house projects, as well as being excellent for employee engagement. Many at the Innovation Centre have racing experience, past or present, and love being involved.

“I have thoroughly enjoyed working with UoN’s Formula Student technical team setting up inverter control of their electric motors and characterising their electric transmission," explained Chris Adams, GKN Automotive’s Software and Development Engineer. "It wasn’t so long ago that I was a competitor myself! Plus working with the team enhanced my understanding of setting up field weakening control”

GKN Automotive Innovation Centre looks forward to seeing their FS Teams in action at Silverstone.