Articles

David Pitt is a project engineer at Atkins Nuclear & Power Group, where he manages the Seismic Damage Tolerance Assessment project.

“I’ve been at Atkins for two years now,” he says. “Previously I was in New Zealand working as a senior engineer in the hydroelectric sector, and before that I was an engineer in the oil and gas industry. Only recently has my role focused on project management.

“I have been managing the Seismic Damage Tolerance Assessment project, in which we develop and maintain a suite of software tools that collectively we call GCORE. I’m accountable for cost, time and quality expectations, the health and safety of all the staff, change management and risk management – thinking about things that could prevent us from achieving our objectives.

“I’m also responsible for project documents and reporting, and then capability management, which is making sure we’ve got the right people and IT resources to get the job done. I’m in regular communications with the client, EDF – who own and operate all generating nuclear reactors in the UK – to discuss new scope and if there are any updates to their requirements.”

Shake it up

“We seismically assess each of the UK’s AGR reactor cores. These assessments are used by EDF as evidence in their safety cases, demonstrating that the control rods can always be used to shut down and hold down a reactor, even during a one-in-10,000-year earthquake.

“To produce these, one of the industry’s most complex models is required to simulate the effect of ground motions on the reactor core’s structural components.

“There are three key challenges with this – the biggest is that the core has more than 6,000 graphite components, each with multiple contacts. This means the model is very complex, so we have written custom Abaqus/Explicit user elements to model specific interactions and vastly improve efficiency. Without this technology, our run times of about a day would be in the order of months.

“Another challenge is managing the differences in reactor core design and the age between reactors. The design of graphite bricks and keying arrangement varies between sites, so we use Python scripts to automate the production of the repeating lattice pattern. The physical and dimensional properties of each brick also vary through time, so Python is used to apply this to the model.”

Engineering ‘net zero’

“A third challenge is around quality assurance. The modular approach helps, since we can verify the quality of discrete parts of the code, even before we verify the calculated output. But, even then, how do you know the model is right?

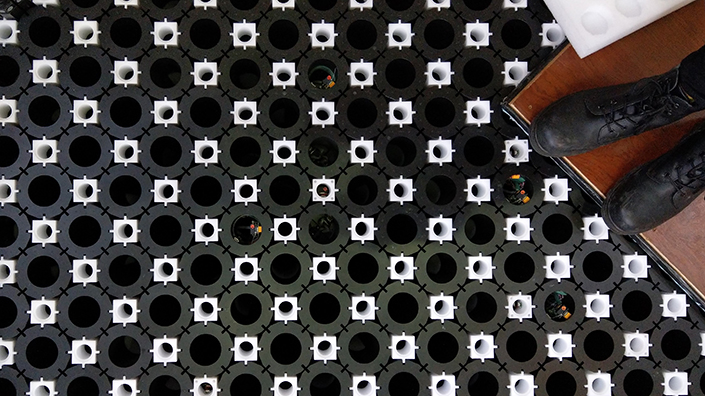

“That’s where our collaboration with the University of Bristol comes to the fore, with their hydraulic shaker table. To validate our models, a quarter-scale model of the reactor core is given the same input motion as our models. Through a complex array of sensors, we can compare a host of test data with our model, letting us validate that the response of the model is correct by comparison with physical behaviour.

A model of a reactor core

“It’s complex yet exciting work, and I think the ground-breaking development work is rewarding in its own right for the team. But we’re also all engineering net zero by supporting regulatory confidence in operating existing infrastructure. That’s what is rewarding, knowing that you’re directly contributing to reducing CO2 emissions.”

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.