But Dublin-born billionaire inventor and engineer Sir David McMurtry still works four days a week, thinking up the next generation of the precision measurement and manufacturing technology, medical robots and 3D metal printers for his company Renishaw.

McMurtry founded Renishaw with Welshman and fellow engineer John Deer after they met in 1972 at Rolls-Royce – which the Irishman had joined as an apprentice after leaving school in 1958.

The Renishaw business grew out of McMurtry’s invention of a touch-trigger probe to measure small-diameter fuel and oil pipes in the early stages of the design of the Rolls-Royce Olympus engine that they were working on at the time. A prototype of the engine is proudly displayed in the lobby of the firm’s HQ, surrounded by leather seats and shelves full of books and journals.

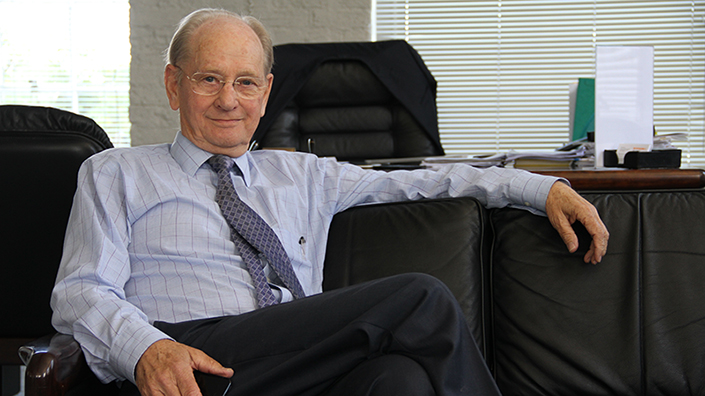

“My role at Rolls-Royce was mainly on the version of that engine for military jets, initially as a project manager,” says McMurtry, sitting in a modest office that overlooks a lake and nature reserve on the sprawling site of the Renishaw HQ, in a green Gloucestershire valley about 40 minutes’ drive from Bristol city centre.

“Then after I’d been promoted to deputy chief designer, I had a role across all the engines, including the Olympus one for the legendary Concorde. I was asked to look at this problem with measuring the pipes, and that was when I became even more involved,” he says.

Precision pays off

The probe evolved into a key precision engineering tool and spun off others that have underpinned Renishaw’s success. Fuelled by McMurtry’s early inventive talent and then his ability to develop, aid and inspire it in his R&D staff, the business that he and Deer have since built has become a FTSE-listed £4bn manufacturing and exporting powerhouse.

Today, Renishaw makes a vast array of products. Aside from 3D printers, there are Raman spectroscopy machines, products used in dental care and brain surgery. There are laser, metal and magnetic encoders, machine-tool probes, styli for them, coordinate measuring machine probes, machine calibration and optimisation products, plus a whole range of accessories, fixtures and software to go with them all.

There’s a good chance that the company’s products were used in the manufacture or inspection of your smartphone, smartwatch, your big-screen TV, your computer or tablet, many of the components in your car and many of the microchips in those products. Spacecraft, aerospace and motorsport manufacturers use Renishaw products, as well.

This is McMurtry’s first interview since handing over the reins of Renishaw to new chief executive Will Lee, an Oxford University graduate whose MBA the company sponsored, and who has worked there for 20 years. After 45 years at the helm, McMurtry has gone back to the role he enjoys the most, R&D. His official title is executive chairman with responsibility for innovation and product strategy.

Focus on the future

He explains his move back to R&D. “I can again focus on what I like doing best,” he says. “My wife jokes that I’m working even harder now than I did previously. Will has worked across many of our business divisions. He knows the business and all of our technology backwards.

“He’s largely focused on the current generation of our technology. I’m solely focused on the next generation. That includes our additive manufacturing, our Neuromate medical robots and our Equator measuring and inspection probe.”

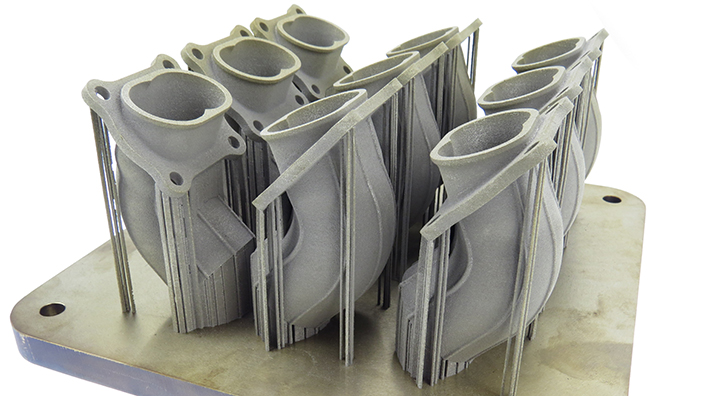

3D printing and medical robots still apparently only bring in a small share of revenue compared to Renishaw’s core products such as the Equator and other precision measurement and metrology products. The group’s latest 3D printer has four lasers, giving it an edge over those of rivals, which mostly have two, including those of GE, which bought several 3D-printer makers last year, but has yet to catch up. McMurtry hopes to ensure that Renishaw maintains its lead.

Renishaw plans to build on its success in 3D printing (Credit: Renishaw)

“We want a lead in making the process completely automated, improving manufacturing speeds and reducing the cost per part. It’s about making the process reliable and taking out the man-hours for customers. We’re learning from improved control of the additive manufacturing process. That’s how we hope to stay ahead.” In short, the next generation of the printer needs to have more lasers and to work faster, but in a controlled way.

“It’s a fast-moving sector and we have to put in a lot of effort to make sure we’re not left behind,” says McMurtry. “Targeting areas our competitors aren’t in helps as well. We are also looking at the role artificial intelligence will play in this.”

Many of Renishaw’s customers need to inspect and manufacture things faster and minimise costs because their margins are tightening. Asia, where the company earns about half its revenues, is a key growth market. A rise in demand for computer chips owing to their increased use in industrial robotics – some of which also use Renishaw motion sensors – and consumer products is also a factor.

Curiosity drives R&D

The company expects China to increasingly take on South Korea in manufacturing more big-screen TVs, while the rise in the number of cars featuring electronic displays also boosts the requirements for high-precision manufacturing.

McMurtry describes R&D as his hobby, and says his curiosity comes from a keen aptitude for maths and science – “I was hopeless at everything else” – from an early age. Model-plane making – “a major distraction to my education” – helped to nurture his innate talent.

“Observation is everything,” he says. One solution that McMurtry came up with – how to make a 3D-printed device that could deliver drugs directly to the brain for the treatment of cancer, Parkinson’s and other diseases – gives an idea of his genius. He was inspired by the bone-anchored hearing aid of someone he met in a pub. He and his design team then copied the way it was hidden behind the ear and incorporated a screw into the bone that went right through the skin.

Reading books of university research abstracts – “one-page summaries of what young researchers and innovators are doing” – also helps to fuel McMurtry’s inventive mind. “Engineering director Geoff McFarland [who also plays a key role in R&D] has just brought back a new pile for me from a conference,” he laughs.

“They’re fascinating. I ask myself: ‘Why didn’t I think of doing that?’ The failure rate of them is enormous. But some of the thinking is interesting.

“I also enjoy visiting manufacturers in the sectors our customers operate in – makers of medical devices and implants, or others making car components, engines, planes or jet engines, electronics and what have you. It’s always interesting to see what they’re doing, hear their thinking and what their needs are.”

Bright ideas abound

Is it becoming more difficult to come up with inventions in this age of exponential progress in technologies such as AI and robots? “No, I don’t think so,” he says. “The present environment is quite stimulating, and opens more doors for new products to be invented. We’re lucky to have a number of up-and-coming inventors within Renishaw. But Dyson did his own thing. Elon Musk is the same. There will be more like them. They can come from anywhere.”

McMurtry is not concerned that the business might lose its inventive impetus to some degree when he has to step down. There’s a sense that he might be irreplaceable.

“When I step down, I’ll let you know,” he replies. “When I wake up in the morning having had a good sleep, I have about two hours when everything tends to be fresh in my mind. Then I come here and do a few sketches. Everything starts with a sketch as far as I’m concerned,” he laughs. On his desk are several of them on graph paper.

He enjoys problem solving and collaborating with his R&D teams. “We have a good dialogue,” he says. “I’ve got solutions from my experiences working in many different areas over the years, that I’ve gained from another division where they haven’t yet worked, or I’ll suggest someone else who might help them.

McMurtry is 'solely focused on the next generation of technology'

“When I’ve drawn my sketches, I get feedback from the R&D staff, then I talk to Geoff and others to get their thoughts. We get a rapport going and then we go on to the next phase of the process.

“If I open one of the drawers at my desk, there’s a load more stuff in there that didn’t quite make it past the first stage,” he laughs.

McMurtry’s personal hero is Isambard Kingdom Brunel, regarded as one of the heroes of Britain’s Industrial Revolution and one of the most prolific and ingenious figures in the history of engineering.

“Brunel was an incredible guy, who did incredible things in a short space of time, and with none of the tools and technology that we’ve got today, which makes his achievements all the more remarkable.”

Renishaw helped to fund the establishment of the Being Brunel museum in Bristol, which opened this year on the city’s harbourside. The company is also a sponsor of Aerospace Bristol, the museum that’s home to one of the last remaining Concordes (and the venue for this year’s IMechE annual dinner in November).

“Brunel was really a dynamo, with great drive and ability. Some of his designs are very original. And he got it all funded as well. What he did was unbelievable,” says McMurtry, whose own drive continues to impress.

Is McMurtry the most prolific living inventor in Britain?

The billionaire inventor Sir James Dyson is justly famous. If you don’t own one of his fans or vacuum cleaners, you’ve probably used one of his hand dryers. Given that he is a household name, he might be the first person who comes to mind in answer to the above question.

However, the European Patent Office’s register reveals that, while Dyson has 117 patents to his name, Sir David McMurtry – the co-founder of Renishaw – has at least 195.

The official line from Renishaw is that McMurtry filed 47 patents in his Rolls-Royce days and more than 150 in his time at Renishaw. Most of the latter in turn led to further ones – over 300 being granted to the company, which has more than 1,500 in total.

Renishaw’s patent attorney Tim Jackson adds: “Your search may miss out David’s early patents filed before 1977 when the European Patent Office was founded. David has been inventing for a longer period than James Dyson, and of course he’s still inventing today.”

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.